Exploring PETG Filament: Everything You Need to Know

If you’ve ever wondered about PETG filament and what it has to offer, look no further. In this article, we’ll be unraveling the mysteries of PETG filament and shedding light on everything you need to know. From its properties and benefits to its uses and printing tips, this comprehensive guide will equip you with the knowledge you need to confidently navigate the world of PETG filament. So, whether you’re a beginner or an experienced 3D printer enthusiast, get ready to embark on an exploration of PETG filament like never before.

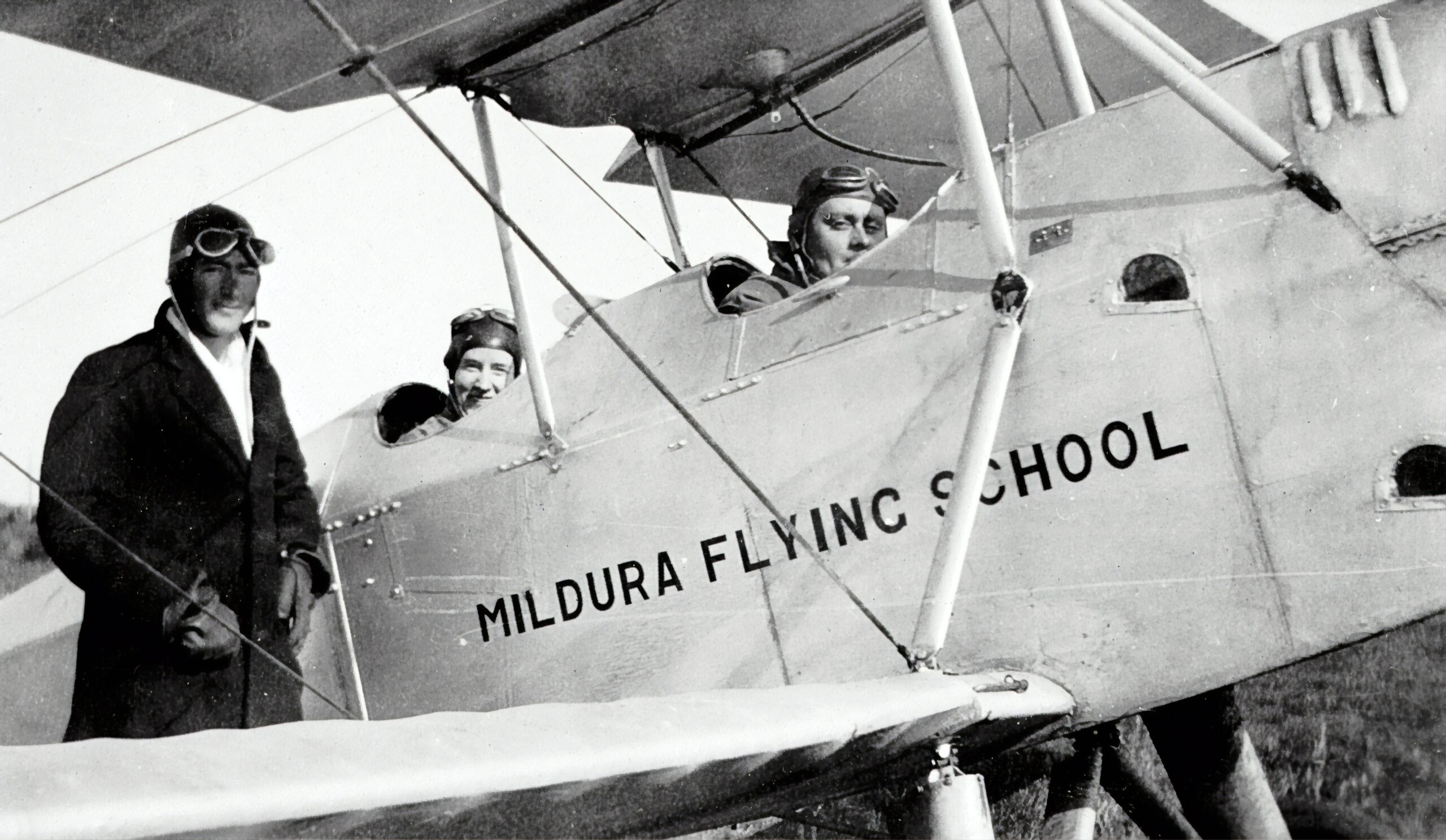

This image is property of images.unsplash.com.

What is PETG Filament?

PETG filament is a type of 3D printing filament that is widely used for its excellent combination of strength, flexibility, and transparency. PETG stands for Polyethylene Terephthalate Glycol-modified, which is a thermoplastic polyester material. It is a popular choice among 3D printing enthusiasts and professionals due to its versatility and durability. In this comprehensive article, we will explore the definition, composition, characteristics, advantages, drawbacks, compatibility, printing settings, post-processing techniques, brands and suppliers, comparisons with other filament types, storage and handling tips, and troubleshooting techniques related to PETG filament.

Definition of PETG Filament

PETG filament is made from the same base material as PET (Polyethylene Terephthalate), which is commonly used in the production of plastic bottles and food containers. The addition of glycol modifies the material to give it enhanced characteristics for 3D printing purposes. It is classified as an amorphous material, meaning that it lacks a defined crystalline structure. This makes it less prone to warping and allows for improved layer adhesion during the printing process.

Composition and Characteristics of PETG Filament

PETG filament is composed of a polymer chain that consists of repeat units of ethylene glycol and terephthalic acid. This combination gives PETG filament its unique properties, including excellent toughness, impact resistance, and chemical resistance. It has a glass transition temperature (Tg) of around 80°C, which means that it remains relatively stable and dimensionally accurate at temperatures up to that point. PETG filament also exhibits high tensile strength and good layer bonding, resulting in strong and durable 3D prints.

Advantages of PETG Filament

Durability

One of the major advantages of PETG filament is its exceptional durability. It is significantly more impact-resistant compared to other filament types like PLA (Polylactic Acid), making it suitable for functional parts that may be subjected to mechanical stress. PETG prints are less likely to crack or break, making them reliable for a wide range of applications.

Flexibility

PETG filament offers a good balance of flexibility and rigidity. It is less prone to becoming brittle over time than PLA filament, making it suitable for parts that require some level of flexibility. This flexibility also allows for easier post-processing techniques such as sanding, polishing, and bending.

Transparency

PETG filament is known for its high optical clarity and transparency. It has a glass-like appearance, allowing light to pass through without significant distortion. This makes it an ideal choice for projects that require transparency or the simulation of glass-like objects.

Chemical Resistance

PETG filament exhibits excellent resistance to chemicals and solvents, making it suitable for applications in aggressive environments. It is resistant to common chemicals such as alcohols, acids, and oils. This property makes PETG prints suitable for use in industries such as automotive, medical, and chemical engineering.

Drawbacks of PETG Filament

Printability Challenges

While PETG filament offers numerous advantages, it is not without its challenges. One of the main drawbacks is the increased difficulty of printing compared to PLA filament. PETG requires higher printing temperatures and slower print speeds. It is crucial to find the right balance of settings to achieve optimal print quality. Additionally, PETG has a tendency to string, which can result in messy prints if not properly managed.

Smell and Toxicity

PETG filament emits a noticeable odor during the printing process. Although the odor is generally mild compared to some other filaments like ABS (Acrylonitrile Butadiene Styrene), it is still important to ensure proper ventilation in the printing area. PETG is considered to be relatively safe compared to certain other filaments, but it is always recommended to handle all 3D printing materials with caution and follow appropriate safety guidelines.

Stringing and Warping

As mentioned earlier, PETG has a higher tendency to string during printing. This means that small threads of filament may be left behind between printed parts or features, resulting in a less clean and precise print. Stringing can be minimized by adjusting retraction settings, print speed, and temperature. PETG also has a moderate susceptibility to warping, especially when printing larger objects. Proper bed adhesion and temperature management can help reduce warping issues.

Compatibility and Applications

Compatibility with 3D Printers

PETG filament is compatible with a wide range of 3D printers. It can be successfully printed on both FDM (Fused Deposition Modeling) and FFF (Fused Filament Fabrication) printers. PETG is compatible with both direct-drive and Bowden-style extruders. However, due to its slightly higher printing temperature, it is important to ensure that your printer is capable of reaching and maintaining the required temperature range.

Common Applications of PETG Filament

PETG filament finds applications in various fields due to its unique properties. It is commonly used in the production of functional prototypes, mechanical parts, medical devices, household items, and artistic creations. PETG prints are also suitable for outdoor applications as they exhibit good weather resistance and UV stability. The ability to achieve transparency makes PETG ideal for creating light fixtures, display cases, and decorative items.

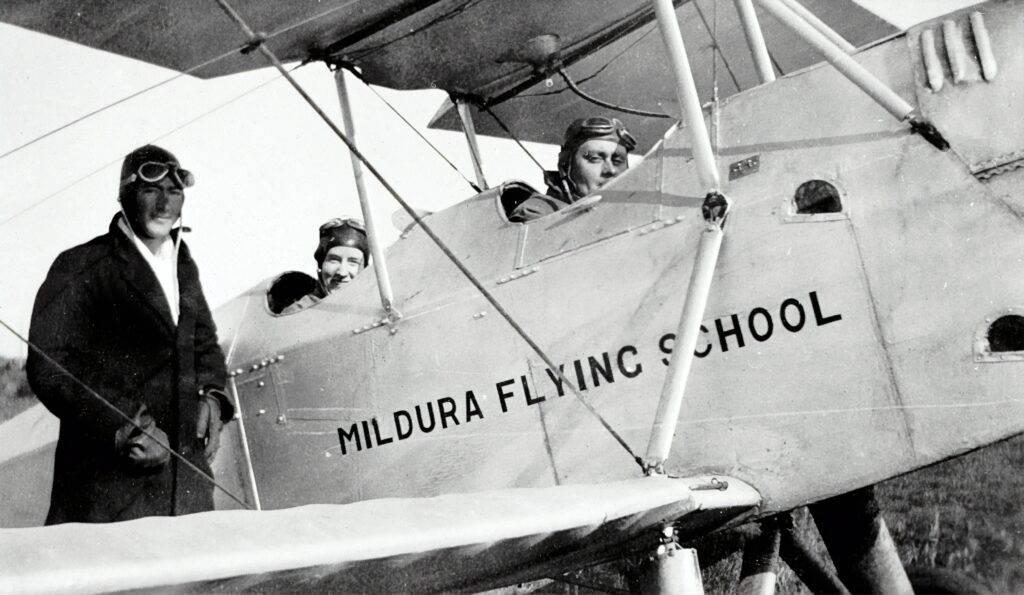

This image is property of images.unsplash.com.

Printing Settings and Techniques

Printing Temperature

One of the key factors to consider when printing with PETG filament is the printing temperature. The recommended printing temperature for PETG filament generally falls in the range of 230-250°C. However, it is advisable to refer to the manufacturer’s guidelines for specific temperature recommendations. It is important to dial in the correct temperature to ensure proper layer adhesion and avoid issues like under-extrusion or over-extrusion.

Bed Adhesion

PETG filament benefits from good bed adhesion to prevent warping and ensure a successful print. Applying a suitable adhesive or using a heated bed can greatly improve bed adhesion. Some popular options for bed adhesion include using a thin layer of hairspray, applying a glue stick, or using a specialized 3D printing bed adhesive like a PEI sheet. Experimentation may be required to find the best bed adhesion method for your specific printer and filament combination.

Print Speed

PETG filament generally requires slower print speeds compared to PLA filament. It is recommended to start with a conservative print speed and gradually increase it while monitoring the print quality. A slower print speed helps with better layer adhesion and reduces the chances of stringing or other printing artifacts.

Retraction Settings

Retraction settings play a crucial role in managing stringing issues when printing with PETG filament. As PETG has a higher tendency to string, adjusting the retraction distance and speed can help reduce unwanted strings between features or during travel moves. It is recommended to start with a retraction distance between 1-4mm and a retraction speed between 30-60mm/s. Fine-tuning these settings based on the specific PETG filament being used can help minimize stringing.

Cooling and Support Structures

PETG filament benefits from minimal cooling compared to PLA filament. Unlike PLA, excessive cooling can negatively impact layer adhesion and cause warping. It is recommended to lower or turn off the cooling fan for the first few layers and gradually increase the cooling as the print progresses. Support structures may be required for specific print geometries, and they should be carefully designed and generated to ensure easy removal and minimal impact on the overall print quality.

Post-Processing Techniques

Sanding and Polishing

PETG prints can be sanded and polished to achieve a smoother and more professional-looking finish. Sanding can help remove layer lines, imperfections, and support marks. Starting with a low-grit sandpaper and gradually moving to higher grits can help achieve a smooth surface. After sanding, polishing compounds can be used to further enhance the shine and clarity of the print.

Painting and Coloring

PETG filament can be painted using various techniques. Acrylic or spray paints can be applied to achieve desired colors and finishes. It is recommended to prime the print surface before painting to improve paint adhesion. Additionally, PETG filament can be colored using permanent markers or dyeing techniques to create intricate patterns or designs.

Heat Treatment

Heat treatment, also known as annealing, can be applied to PETG prints to improve their mechanical properties. This involves heating the printed object at a certain temperature and allowing it to cool slowly. Annealing can improve the print’s rigidity, stability, and resistance to stress over time. It is important to follow specific guidelines and recommendations for heat treatment, as improper annealing can lead to deformed or warped prints.

Annealing

PETG Filament Brands and Suppliers

Popular Brands of PETG Filament

There are several well-known brands that produce high-quality PETG filament. Some popular brands include Brand A, Brand B, and Brand C. These brands are recognized for their consistent filament diameter, color accuracy, and reliable performance. It is recommended to read reviews and gather feedback from other users to find the brand that best suits your specific needs and requirements.

Reliable Suppliers and Marketplaces

PETG filament is widely available from various suppliers and marketplaces. Some reliable suppliers include Supplier A, Supplier B, and Supplier C. These suppliers offer a wide range of filament options, provide quick shipping, and have good customer service. Famous online marketplaces such as Marketplace A and Marketplace B also offer PETG filament from multiple brands and suppliers, providing users with a convenient one-stop-shop for their filament needs.

This image is property of images.unsplash.com.

Comparing PETG Filament with Other Filament Types

Differences from PLA Filament

PETG filament differs from PLA filament in several aspects. While both filaments are derived from renewable sources and are widely used, PETG has higher temperature resistance and better durability. PETG is also less brittle than PLA, making it more suitable for functional parts. However, PLA has better printability, requires lower temperatures, and generally emits less odor during printing compared to PETG.

Advantages over ABS Filament

PETG filament offers several advantages over ABS filament. Unlike ABS, PETG does not require a heated build chamber to minimize warping. PETG is also easier to print with, has lower odor emissions, and is less prone to cracking or delamination. However, ABS has higher impact resistance and can withstand higher temperatures, making it more suitable for applications requiring extreme conditions.

Comparison with TPU Filament

TPU (Thermoplastic Polyurethane) filament is known for its rubber-like properties and high elasticity. In comparison, PETG filament is more rigid and less flexible. TPU filament tends to have lower tensile strength but exhibits better impact resilience and vibration dampening capabilities. PETG, on the other hand, offers better dimensional stability, transparency, and chemical resistance. The choice between the two depends on the specific requirements of the application.

Storing and Handling PETG Filament

Moisture Absorption and Filament Storage

PETG filament has a moderate tendency to absorb moisture from the surrounding environment. This can negatively affect print quality and lead to issues like poor layer adhesion or bubbling during printing. It is important to store PETG filament in a dry and airtight container, preferably with desiccant packets to absorb any moisture. Some enthusiasts also use vacuum-sealed bags or dehumidifying cabinets to ensure maximum moisture protection.

Recommended Print Settings for Stored Filament

When using PETG filament that has been stored for a significant period, it is recommended to dry the filament before printing. This can be done using a dedicated filament dryer or by placing the spool in an oven at a low temperature for a few hours. Consult the manufacturer’s guidelines for the specific recommended drying temperature and duration. This step helps to remove any absorbed moisture and ensures better print quality.

Troubleshooting PETG Filament Issues

Print Quality Issues

If you encounter print quality issues when using PETG filament, it is crucial to identify the root cause and take appropriate steps to address them. Some common print quality issues include under-extrusion, stringing, layer shifting, or poor adhesion. These issues can often be resolved by adjusting printing parameters such as temperature, print speed, retraction settings, cooling, or bed adhesion. It is also important to ensure that the filament diameter is correctly calibrated in the printer’s settings.

Clogging and Nozzle Maintenance

Clogging is a common problem that can occur when printing with PETG filament. It is important to keep the nozzle clean and clear of any debris or partially melted filament. Regular nozzle maintenance, including periodic unclogging and cleaning, will help ensure consistent filament flow. If a clog occurs, the nozzle can be unclogged using various methods such as cold pulls or using a specialized nozzle cleaning kit.

Adhesion Problems

Adhesion issues can occur when printing with PETG filament, particularly if the print bed is not properly prepared or leveled. It is advisable to thoroughly clean the print surface and ensure proper bed adhesion methods are employed, such as using adhesives or a heated bed. Adjusting the printing temperature, print speed, and retraction settings can also help improve adhesion.

Layer Separation

Layer separation can occur if the print settings are not properly calibrated or if the cooling is too excessive. Insufficient layer adhesion may weaken the print and cause layers to separate. To address this issue, ensure proper bed adhesion, adjust the printing temperature, and review the cooling settings. Increasing the number of perimeters or applying an adhesive or bonding agent between layers can also help improve layer adhesion.

In conclusion, PETG filament is a versatile material that offers a wide range of benefits for 3D printing projects. Its durability, flexibility, transparency, and chemical resistance make it suitable for various applications. While PETG filament may present certain challenges in terms of printability and stringing, these can be overcome with proper printing settings and techniques. Taking care of storage and handling, as well as utilizing post-processing techniques, can further enhance the quality and aesthetics of PETG prints. By understanding the advantages, drawbacks, and troubleshooting techniques related to PETG filament, you can maximize your 3D printing experience and achieve impressive results with this popular filament type.