Exploring the Advantages of 3D Manufacturing

Have you ever wondered about the amazing possibilities of 3D manufacturing? With this innovative technology, objects are created layer by layer, allowing for intricate and detailed designs that were once unimaginable. In this article, we will delve into the world of 3D manufacturing and explore its numerous advantages. From cost-effectiveness to customization options, this revolutionary method is transforming the way products are made. So, come along on this journey as we discover the incredible benefits of 3D manufacturing.

Advantages of 3D Manufacturing

3D manufacturing, also known as additive manufacturing or 3D printing, is a revolutionary technology that has transformed the world of manufacturing. With 3D printing, objects are created by laying down successive layers of material until the desired shape is achieved. This innovative process offers numerous advantages over traditional manufacturing methods, making it a game-changer in various industries. In this article, we will explore the advantages of 3D manufacturing and how it can benefit you.

This image is property of pixabay.com.

Reduced Costs

One of the most significant advantages of 3D manufacturing is the potential for reduced costs. Unlike traditional manufacturing methods, which often require expensive tooling and molds, 3D printing eliminates the need for such investments. With 3D printing, you can create complex designs and prototypes directly from digital files, significantly reducing the upfront costs associated with manufacturing. Moreover, 3D printing allows for more efficient use of materials, minimizing waste and further lowering production costs. Whether you are a small business or a large corporation, the cost-saving potential of 3D manufacturing is certainly worth considering.

Faster Production

Another major advantage of 3D manufacturing is its ability to accelerate the production process. Traditional manufacturing methods can be time-consuming, requiring multiple steps and processes. In contrast, 3D printing allows for the rapid creation of objects with minimal human intervention. With the ability to print objects layer by layer, 3D manufacturing can produce parts and prototypes in a fraction of the time it takes using conventional methods. This increased speed not only enhances productivity but also enables companies to respond quickly to market demands and reduce time-to-market for new products.

Design Flexibility

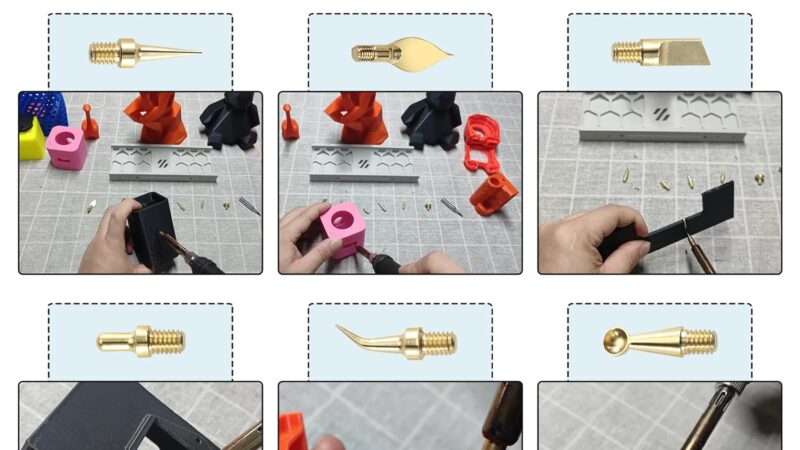

With 3D manufacturing, you have unparalleled design flexibility. Traditional manufacturing methods often impose limitations on the complexity and intricacies of designs, requiring compromises to be made. However, 3D printing breaks these barriers, allowing you to bring even the most intricate and complex designs to life. The layer-by-layer construction process of 3D printing enables the creation of intricate geometries, internal cavities, and complex shapes that were previously unattainable. This design freedom opens up a world of possibilities, enabling you to unleash your creativity and explore new avenues of product development.

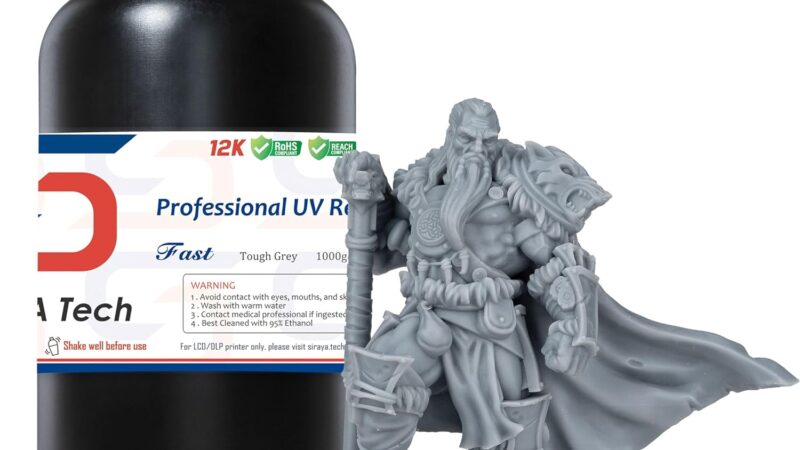

Complex Geometry

One of the standout advantages of 3D manufacturing is its ability to produce objects with complex geometries. Traditional manufacturing methods struggle with intricate shapes and internal features, often requiring costly and time-consuming machining processes. In contrast, 3D printing excels at creating objects with complex geometries, thanks to its layer-by-layer build approach. This enables the production of intricate and interconnected designs, such as lattice structures, that offer immense strength while minimizing weight. Whether you are designing lightweight aerospace components or intricate medical implants, 3D manufacturing can help bring your vision to life.

This image is property of pixabay.com.

Prototyping

Prototyping is a critical phase in product development, allowing designers and engineers to evaluate and refine their ideas before moving to mass production. 3D manufacturing offers tremendous advantages in prototyping, making it an invaluable tool for innovators. With 3D printing, you can rapidly produce prototypes directly from digital designs, enabling you to iterate and test your concepts quickly. This accelerated prototyping process allows for faster feedback loops, enabling you to refine your designs and make necessary improvements. By reducing the time and costs associated with prototyping, 3D manufacturing empowers you to develop better products in a more efficient manner.

Customization

In today’s market, customization is becoming increasingly important. Consumers expect products that cater to their unique needs and preferences, and 3D manufacturing offers the ability to deliver just that. Through 3D printing, you can easily customize products to meet individual requirements, offering a level of personalization that traditional manufacturing methods struggle to achieve. From personalized consumer goods to customized medical devices, 3D manufacturing enables companies to create products tailored to the specific needs of their target audience. By embracing customization, you can enhance customer satisfaction and gain a competitive edge in the market.

This image is property of pixabay.com.

Improved Efficiency

Efficiency is a crucial factor in manufacturing, and 3D printing excels in this area. With its streamlined and automated production process, 3D manufacturing minimizes human error and ensures consistent quality. The ability to print objects directly from digital designs eliminates the need for manual intervention and reduces the risk of errors commonly associated with traditional manufacturing processes. Additionally, 3D printing allows for the consolidation of multiple parts into a single component, simplifying assembly processes and reducing the number of required components. This increased efficiency translates into faster production times, reduced labor costs, and improved overall productivity.

Reduced Waste

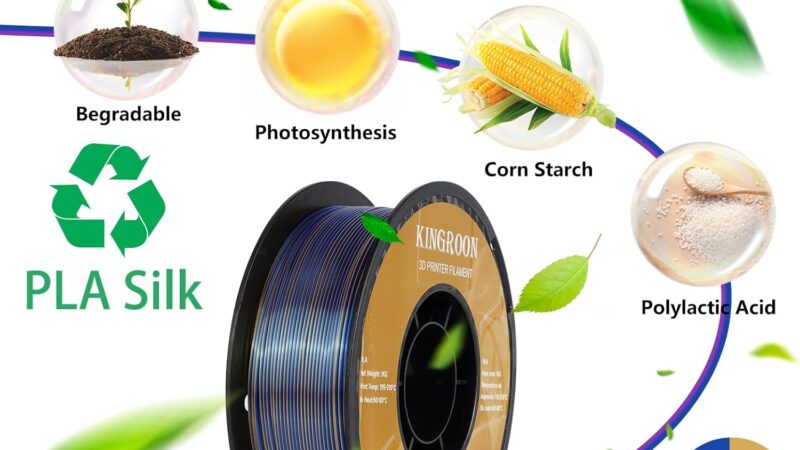

Traditional manufacturing often generates substantial waste, whether from excess materials, machining processes, or rejected parts. 3D manufacturing offers a more sustainable alternative by minimizing waste and optimizing material usage. With 3D printing, you only use the exact amount of material required to build the desired object, eliminating unnecessary waste. Moreover, 3D printing enables the recycling and repurposing of materials, further reducing environmental impact. By reducing waste, 3D manufacturing helps companies save on material costs and promotes sustainable practices, benefitting both the bottom line and the planet.

Sustainable Manufacturing

In today’s world, sustainability and environmental consciousness are of paramount importance. 3D manufacturing aligns perfectly with these values by offering a more sustainable approach to production. By minimizing waste, optimizing material usage, and reducing the need for traditional manufacturing processes, 3D printing significantly reduces energy consumption and carbon emissions. Additionally, the ability to produce objects on-demand and in localized settings reduces the need for long-distance transportation, further minimizing the ecological footprint. With 3D manufacturing, you can embrace sustainable manufacturing practices and contribute to a greener future.

Increased Innovation

Last but not least, 3D manufacturing fosters increased innovation in various industries. The design freedom, cost reductions, and rapid prototyping capabilities offered by 3D printing allow designers and engineers to push the boundaries of what is possible. From creating lightweight yet durable structures to developing intricate medical devices and personalized consumer goods, 3D manufacturing encourages innovation and sparks creativity. The ability to quickly iterate designs, test concepts, and bring ideas to life empowers individuals and companies to unlock new opportunities and drive industry advancements.

In conclusion, 3D manufacturing offers a plethora of advantages that can revolutionize the way products are designed and produced. From reduced costs and faster production to design flexibility and increased innovation, the benefits of 3D manufacturing are undeniable. Whether you are a small business, a large corporation, or an individual innovator, embracing 3D printing can enhance your competitiveness, accelerate your time-to-market, and pave the way for a more sustainable and innovative future. So why wait? Embrace the advantages of 3D manufacturing today and unlock a world of possibilities.