Innovative Bamboo 3D Printer Revolutionizing Manufacturing

Have you heard about the innovative Bamboo 3D Printer that is revolutionizing the manufacturing industry? This groundbreaking technology is changing the game by impressively using bamboo as its printing material. With this remarkable advancement, the possibilities are endless!

Imagine the wonders of this Bamboo 3D Printer in manufacturing. It not only provides a sustainable solution but also allows for the creation of complex and intricate designs. The durability and flexibility of bamboo make it an ideal material for various products, from furniture to household items. With this revolutionary printer, you have a new level of creativity and eco-friendly manufacturing at your fingertips. Buckle up for a thrilling ride into the future of manufacturing with the Bamboo 3D Printer!

This image is property of images.unsplash.com.

Introduction to Bamboo 3D Printer

Overview of Bamboo 3D Printing Technology

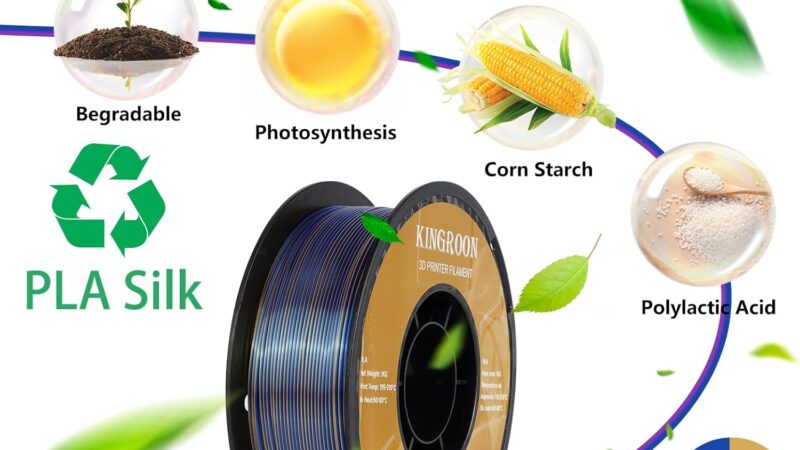

Bamboo 3D printing technology represents a groundbreaking innovation in the manufacturing industry. Combining the versatility of 3D printing with the sustainability of bamboo, this technology has the potential to revolutionize various sectors. Bamboo 3D printers utilize specially formulated bamboo-based filaments to create intricate and durable objects with stunning precision.

Advantages of Bamboo as a Printing Material

Bamboo possesses numerous qualities that make it an ideal material for 3D printing. Firstly, bamboo is incredibly lightweight, making it both easy to manipulate during the printing process and reducing the overall weight of the final product. Secondly, bamboo exhibits excellent strength and durability, allowing for the creation of robust objects that can withstand everyday use. Additionally, bamboo’s natural beauty and grain textures lend a unique aesthetic appeal to the printed products. Finally, bamboo is a highly renewable resource, which contributes to the sustainability and eco-friendliness of bamboo 3D printing.

Applications of Bamboo 3D Printing

Bamboo-Based Furniture Manufacturing

Bamboo 3D printing opens up a world of possibilities in the realm of furniture manufacturing. Traditionally, furniture production involves processes that generate a significant amount of waste and require large quantities of raw materials. With bamboo 3D printing, furniture designers and manufacturers can create custom pieces with intricate designs, minimizing material waste. The lightweight yet sturdy nature of bamboo also makes it suitable for creating ergonomic and sustainable furniture.

Bamboo 3D Printing in Construction Industry

The construction industry can benefit greatly from the integration of bamboo 3D printing technology. Bamboo-based filaments can be used to produce complex architectural components, such as wall panels, flooring, and structural elements. These 3D printed bamboo components offer exceptional strength and durability, making them a viable alternative to traditional construction materials. Furthermore, bamboo’s rapid growth rate and abundance make it an environmentally friendly choice for sustainable construction practices.

Bamboo-Based Art and Crafts

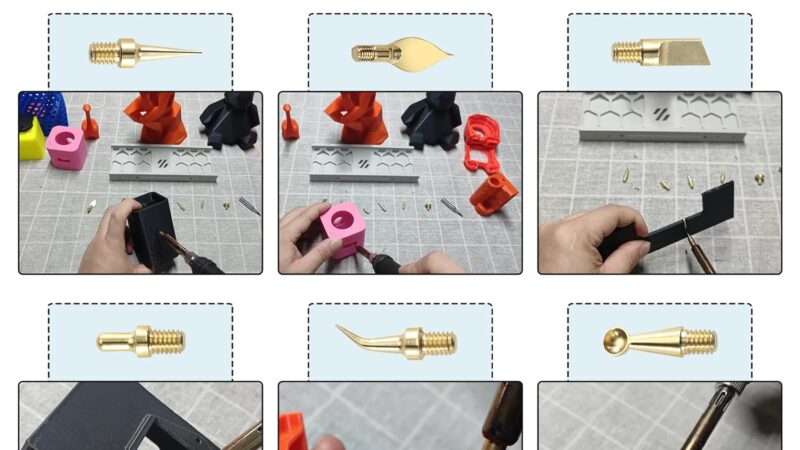

Artists and crafters can explore new realms of creativity with bamboo 3D printing. The ability to print intricate and delicate designs in bamboo-based filaments allows for the production of unique sculptures, jewelry, and decorative items. The natural textures and grain patterns of bamboo add an organic and aesthetically pleasing quality to these artistic creations. Bamboo 3D printing in the art world combines the benefits of traditional craftsmanship with cutting-edge technology.

Bamboo Biomaterials in Medical Field

Bamboo 3D printing also holds great potential in the medical field. Bamboo-based biomaterials can be used to create prosthetics, orthopedic implants, and surgical instruments. The lightweight nature of bamboo ensures greater comfort and convenience for patients, while the strength and durability of printed bamboo products provide reliable support and functionality. Additionally, bamboo’s antibacterial properties make it an ideal material for medical applications, reducing the risk of infections.

Environmental Impact of Bamboo 3D Printing

Sustainability of Bamboo as a Renewable Resource

Bamboo is one of the most sustainable and renewable resources available. With its rapid growth rate and ability to regenerate quickly, bamboo can be harvested without causing significant harm to the environment. Unlike traditional materials derived from trees, bamboo reaches maturity in just a few years, while trees may take decades to grow. This makes bamboo a highly attractive option for eco-friendly manufacturing processes and reduces the pressure on natural forests.

Reduced Carbon Footprint

Bamboo 3D printing significantly reduces the carbon footprint associated with traditional manufacturing methods. The process of extracting and processing raw materials, such as metals and plastics, often involves energy-intensive and polluting practices. In contrast, bamboo cultivation and harvesting require minimal energy inputs. By utilizing bamboo-based filaments, 3D printing minimizes the environmental impact of manufacturing by reducing greenhouse gas emissions and energy consumption.

Promoting Biodiversity and Ecosystem Restoration

The cultivation of bamboo for 3D printing purposes can contribute to the restoration of ecosystems and the preservation of biodiversity. Bamboo plantations provide habitat for various plant and animal species, promoting ecological balance. Furthermore, bamboo helps prevent soil erosion and improves water quality, making it an essential component of sustainable land management practices. By incorporating bamboo 3D printing into manufacturing, we can support the conservation and restoration of fragile ecosystems worldwide.

Challenges and Innovations in Bamboo 3D Printing

Enhancing Printing Precision and Accuracy

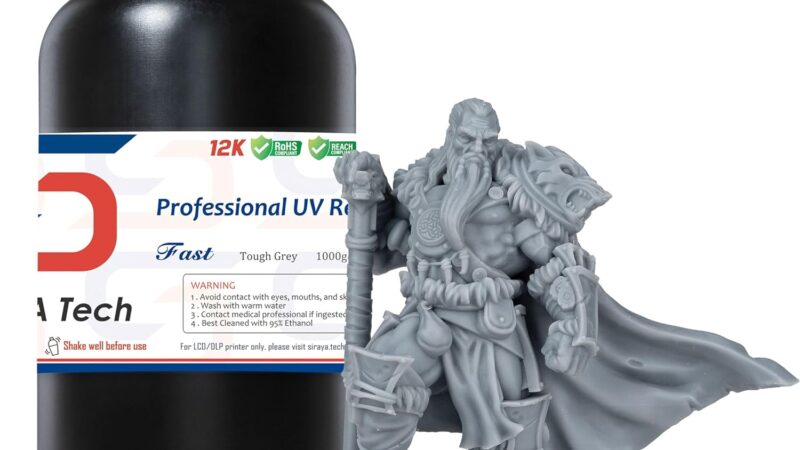

One of the key challenges in bamboo 3D printing is achieving high printing precision and accuracy. Bamboo, with its natural grain patterns and unique structural properties, requires innovative printing techniques to ensure the integrity and quality of the final products. Researchers and engineers are continuously exploring advanced printing algorithms and hardware modifications to enhance the precision and accuracy of bamboo 3D printing.

Developing Specialized Bamboo-Based Filaments

To fully leverage the potential of bamboo as a printing material, the development of specialized bamboo-based filaments is crucial. These filaments need to exhibit optimal printing properties, such as excellent layer adhesion, minimal warping, and good heat resistance. Researchers are actively working on formulating bamboo filaments that meet these requirements, paving the way for more versatile and reliable bamboo 3D printing.

Exploring New Bamboo Composite Materials

Innovations in bamboo composite materials are another avenue of exploration in bamboo 3D printing. By combining bamboo fibers with other natural or synthetic materials, researchers aim to enhance the mechanical properties and functionality of printed objects. Bamboo composites can offer improved strength, flexibility, and resistance to external factors. The development of new bamboo composite materials widens the range of applications for bamboo 3D printing technology.

This image is property of images.unsplash.com.

Current Bamboo 3D Printer Models

Overview of Available Bamboo 3D Printers

The market for bamboo 3D printers is still relatively niche but growing steadily. Currently, there are several models available from various manufacturers, each with its unique features and capabilities. These printers come in different sizes, offering options for both small-scale applications and larger industrial projects. Some of the key players in the bamboo 3D printing industry include companies such as BambooPrints, EcoBam, and Green3D.

Comparison of Features and Capabilities

When choosing a bamboo 3D printer, several factors need to be considered, including printing speed, build volume, resolution, and compatibility with different bamboo-based filaments. Each printer model has its strengths and limitations. For example, BambooPrints is known for its high-resolution printing capabilities, while Green3D specializes in large-scale production. It is essential for users to assess their specific printing needs and compare the features and capabilities of different models before making a decision.

Future Prospects and Impact on Manufacturing

Integration of Bamboo 3D Printing in Large-Scale Production

As bamboo 3D printing technology continues to advance, its integration into large-scale manufacturing processes becomes increasingly viable. The ability to produce customized and intricate designs with speed and efficiency presents a significant advantage for mass production. With further innovations in printing speed and automation, bamboo 3D printing has the potential to transform the manufacturing industry, enabling more sustainable and flexible production methods.

Transformation of Supply Chains

The adoption of bamboo 3D printing technology can have a profound impact on supply chains. Traditional supply chains often involve complex and lengthy processes, including sourcing raw materials, transportation, and inventory management. By incorporating bamboo 3D printing, manufacturers can streamline their supply chains, as the raw material can be grown and processed locally, reducing transportation and logistics costs. This transformation empowers manufacturers to respond quickly to market demands and reduce their environmental footprint.

Democratizing Manufacturing Processes

Bamboo 3D printing has the potential to democratize manufacturing processes by making them more accessible and cost-effective. The versatility and affordability of bamboo as a printing material, combined with the increasing availability of affordable 3D printers, empower individuals and small businesses to create their products. This shift towards decentralized manufacturing promotes innovation and entrepreneurship, fostering economic growth and creativity within communities.

This image is property of images.unsplash.com.

Collaborations and Partnerships in Bamboo 3D Printing

Academic Institutions and Research Centers

Academic institutions and research centers play a vital role in driving the development and advancement of bamboo 3D printing technology. Collaborations between universities, research institutions, and industry partners facilitate knowledge exchange, interdisciplinary research, and the exploration of new applications. These partnerships contribute to the growth of the bamboo 3D printing ecosystem and its practical implementation in various fields.

Industry Partnerships for Bamboo 3D Printing

Partnerships between manufacturers, designers, and suppliers are essential for the successful integration of bamboo 3D printing into existing industries. By working together, companies can pool their expertise, resources, and insights to overcome challenges and maximize the potential of bamboo 3D printing. Joint ventures and collaborations enable the sharing of best practices and the development of innovative solutions that benefit the entire industry.

Government Initiatives and Funding

Government initiatives and funding support are instrumental in driving the growth and adoption of bamboo 3D printing technology. Governments around the world can provide grants, subsidies, and incentives to encourage research and development in the field. Additionally, regulatory frameworks and standards can be established to ensure the safe and responsible use of bamboo 3D printing technology. Government support fosters an environment conducive to innovation and helps accelerate the development of sustainable manufacturing practices.

Bamboo 3D Printing in Developing Countries

Addressing Local Manufacturing Needs

Bamboo 3D printing holds tremendous potential for addressing local manufacturing needs in developing countries. By utilizing locally available bamboo resources, communities can establish small-scale production facilities and create products that cater specifically to their needs. This localized manufacturing approach reduces dependence on imports, stimulates local economies, and empowers communities to take control of their development.

Empowering Local Communities and Economy

The introduction of bamboo 3D printing in developing countries can bring about economic empowerment for local communities. By providing access to affordable technology and training, individuals and small businesses can engage in sustainable manufacturing practices and generate income. The ability to produce value-added products from bamboo creates opportunities for entrepreneurship and economic growth, leading to improved livelihoods.

Overcoming Infrastructure Challenges

Developing countries often face infrastructure challenges that can hinder the adoption of advanced manufacturing technologies. However, bamboo 3D printing offers a solution that is adaptable to local conditions. The simplicity and versatility of 3D printers, combined with bamboo’s abundance and ease of cultivation, make it possible to establish decentralized manufacturing hubs even in areas with limited infrastructure. This innovative approach enables communities to overcome infrastructure barriers and harness the benefits of 3D printing technology.

Regulatory and Standardization Considerations

Ensuring Safety and Quality Standards

As bamboo 3D printing technology becomes more prevalent, it is essential to establish safety and quality standards. These standards ensure that the printed objects meet the expected performance and safety requirements. Regulatory bodies and industry associations can collaborate to define these standards and develop testing protocols to assess the quality and reliability of bamboo 3D printed products. By adhering to these standards, manufacturers can instill confidence in consumers and drive widespread adoption.

Regulations for Bamboo as a Building Material

Bamboo has been used as a building material for centuries; however, the advent of bamboo 3D printing introduces new considerations. Regulators and policymakers need to adapt existing building codes and regulations to accommodate bamboo 3D printed structures. This involves addressing issues such as structural integrity, fire resistance, and the long-term durability of 3D printed bamboo components. Clear guidelines and regulations will ensure the safe and responsible use of bamboo 3D printing in the construction industry.

Certifications for Sustainable Bamboo Sourcing

To ensure sustainability in bamboo 3D printing, certifications for responsible and sustainable bamboo sourcing are essential. These certifications provide assurance that the bamboo used in the printing process is harvested in an environmentally friendly and socially responsible manner. Certifying bodies can work with bamboo growers, manufacturers, and 3D printing companies to develop standards for sustainable bamboo production and establish mechanisms for verification and auditing.

Conclusion

Summary of Bamboo 3D Printing Advancements

Bamboo 3D printing technology represents a significant advancement in the manufacturing industry, offering a sustainable and versatile alternative to traditional materials. The lightweight yet robust nature of bamboo, combined with the precision and customization capabilities of 3D printing, enables the creation of innovative products in various sectors.

Future Outlook and Potential Innovations

The future of bamboo 3D printing looks promising, with opportunities for further advancements and innovations. As research and development continue, we can expect to see enhanced printing precision, the emergence of new bamboo composite materials, and the integration of bamboo 3D printing into large-scale manufacturing processes. These advancements have the potential to reshape supply chains, empower local communities, and redefine the way we approach manufacturing.

Bamboo 3D printing is not just a technological advancement; it is a step towards a more sustainable and environmentally conscious manufacturing industry. By harnessing the unique properties of bamboo, we can create functional and aesthetically pleasing products while minimizing our impact on the planet. With continued collaboration, innovation, and investment, bamboo 3D printing has the potential to revolutionize manufacturing, making it more sustainable, accessible, and eco-friendly.