Introduction to 3D Printing: A Beginner’s Guide

Imagine a world where you can turn your wildest ideas into tangible, three-dimensional objects with just the click of a button. A world where you have the power to design, create, and innovate from the comfort of your own home. Well, my friend, welcome to the exciting world of 3D printing.

In this beginner’s guide, we will explore the fascinating realm of 3D printing, its endless possibilities, and how you can get started on your very own 3D printing journey. From understanding the fundamentals of this revolutionary technology to learning about the different types of printers and materials available, we’ll cover it all. So, fasten your seatbelts and get ready to embark on an exhilarating adventure into the world of 3D printing.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a groundbreaking technology that involves creating three-dimensional objects from digital models. Unlike traditional manufacturing methods that involve subtracting material through cutting or molding, 3D printing adds layers of material on top of each other to form a solid object. This process allows for the creation of complex geometries and intricate designs that would be otherwise impossible to achieve using traditional methods. 3D printing has revolutionized various industries and has become increasingly accessible to individuals and businesses alike.

How Does 3D Printing Work?

3D Modeling

The first step in 3D printing is to create or obtain a digital model of the object you want to print. This can be done using specialized 3D modeling software, which allows you to design and manipulate the geometry of the object. Alternatively, you can download pre-existing 3D models from online repositories. Once the model is ready, it needs to be prepared for printing.

Slicing

Before the actual printing process can begin, the digital model needs to be sliced into thin horizontal layers. This is done using slicing software, which takes into account various parameters such as layer thickness, print speed, and material properties. The slicing software generates a file that contains all the information needed for the 3D printer to recreate each layer of the object.

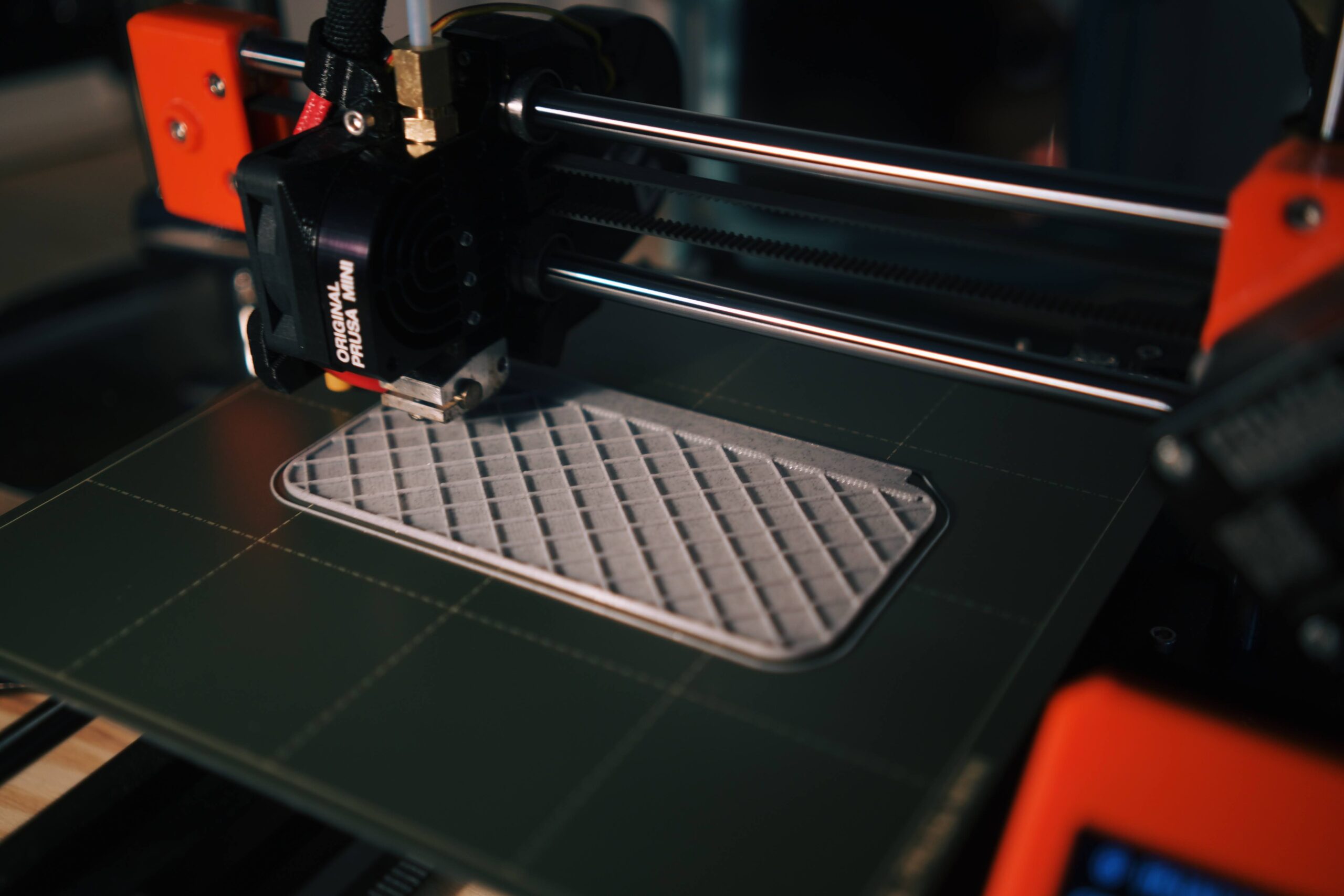

Printing

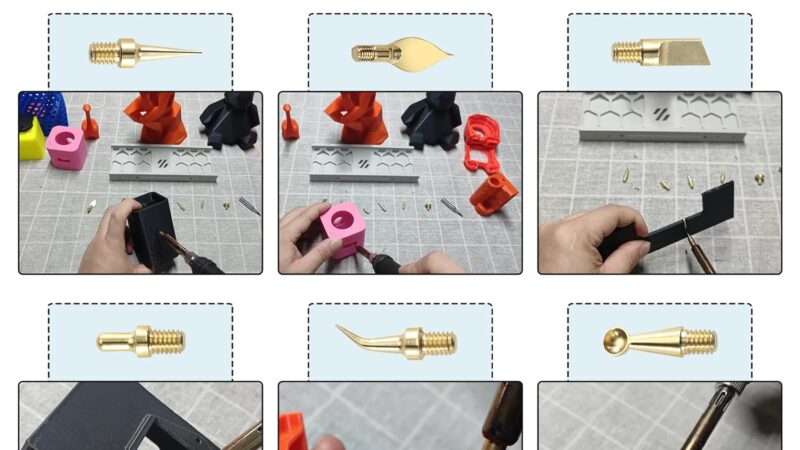

The final step is the printing itself. The sliced file is transferred to the 3D printer, which uses this information to deposit or cure material layer by layer. The printing process varies depending on the technology used, but the general principle remains the same. The printer follows the instructions from the sliced file, gradually building up the object by adding material in a controlled manner. Once the printing is complete, the object may require additional post-processing steps such as removing support structures or sanding to achieve the desired finish.

This image is property of images.unsplash.com.

History of 3D Printing

3D printing has its roots in the 1980s, when the technology was first conceptualized and experimented with by various researchers and engineers. The first successful technique, known as stereolithography, was patented by Charles Hull in 1986. This technique involved using ultraviolet light to selectively cure a liquid resin layer by layer, ultimately creating a solid object.

Since then, 3D printing has evolved at a rapid pace. In the early days, the technology was primarily used for rapid prototyping in industrial settings. However, as advancements in materials and printers occurred, the applications of 3D printing expanded to include various industries and even personal use. Today, 3D printing is becoming increasingly accessible, with desktop printers available for home use and a wide range of materials to choose from.

Types of 3D Printing Technologies

There are several different types of 3D printing technologies, each with its own strengths and limitations. Some of the most common types include:

Fused Deposition Modeling (FDM)

FDM is one of the most widely used 3D printing technologies. It involves melting a thermoplastic filament and extruding it layer by layer to build the object. FDM printers are affordable and easy to use, making them popular among hobbyists and small businesses.

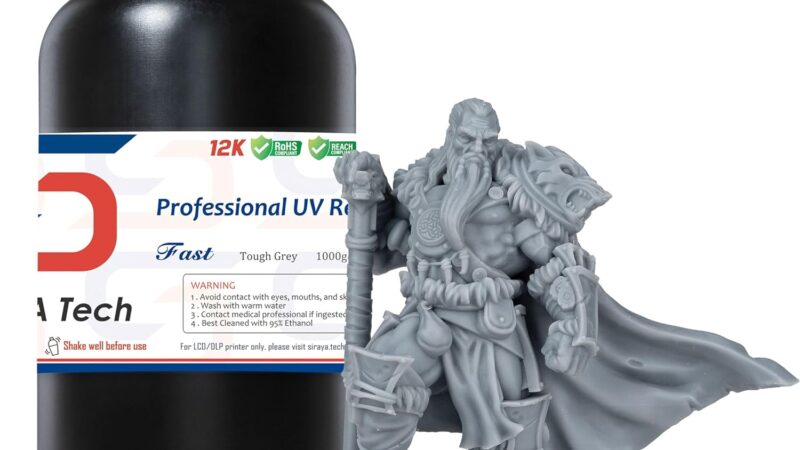

Stereolithography (SLA)

SLA utilizes a photochemical process to solidify liquid resin layer by layer. A light source, typically a UV laser, is used to selectively cure the resin. SLA printers produce high-quality, detailed prints and are often used in industries such as jewelry design and dentistry.

Selective Laser Sintering (SLS)

In SLS, a high-powered laser selectively fuses powdered material, typically nylon, layer by layer to create the object. SLS printers have the advantage of being able to produce functional, durable parts with complex geometries. They are commonly used in industries such as aerospace and automotive.

Digital Light Processing (DLP)

DLP is similar to SLA, but instead of using a laser, it uses a digital light projector to cure the resin. This allows for faster print speeds and can result in smoother finishes. DLP printers are often used in the dental and jewelry industries.

Selective Laser Melting (SLM)

SLM is a metal 3D printing technique that involves using a high-powered laser to melt and fuse metal powder together layer by layer. It is capable of producing strong, fully dense metal parts and is widely used in industries such as aerospace and medical implants.

Electron Beam Melting (EBM)

EBM is another metal 3D printing technique, similar to SLM, but using an electron beam instead of a laser to melt and fuse the metal powder. EBM printers are used for producing large-scale metal parts with complex geometries.

Binder Jetting

Binder jetting involves depositing a liquid binding agent onto a bed of powder material to selectively solidify the layers. This process is repeated until the object is fully formed. Binder jetting is commonly used for producing sand molds for casting.

Material Jetting

Material jetting works by depositing droplets of liquid photopolymer that are then cured using UV light. This process can produce high-resolution, multicolor prints and is often used in the production of prototypes and models.

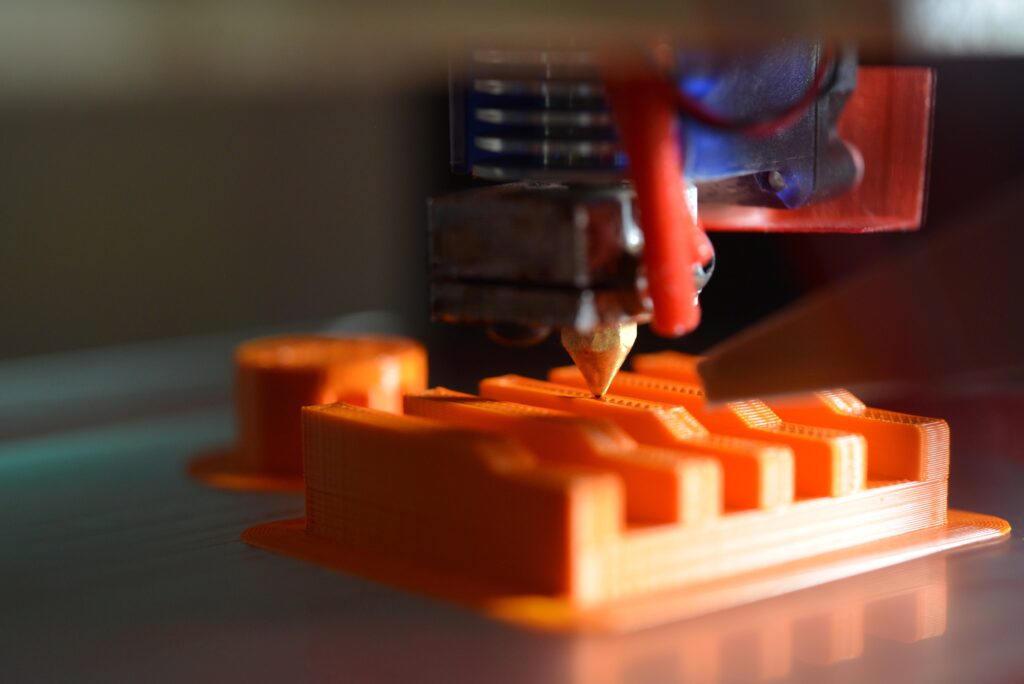

This image is property of images.unsplash.com.

Applications of 3D Printing

3D printing has a wide range of applications across various industries. Some of the key applications include:

Rapid Prototyping

3D printing has revolutionized the prototyping process, allowing for the quick and cost-effective production of concept models and prototypes. This helps to accelerate product development cycles and enables designers and engineers to iterate and refine their designs more efficiently.

Medical and Dental Applications

In the medical field, 3D printing is used for various applications, such as creating patient-specific anatomical models for surgical planning, producing medical implants, and fabricating personalized prosthetics. Similarly, in dentistry, 3D printing is used to create dental models, aligners, and custom implants, among other things.

Aerospace and Automotive Industry

The aerospace and automotive industries have embraced 3D printing for rapid prototyping, functional parts production, and tooling applications. 3D printing enables the production of lightweight yet strong components with complex geometries, leading to improved performance and fuel efficiency.

Education and Research

3D printing has found its way into educational institutions, providing students with hands-on experience in designing and creating objects. It is also widely used in research laboratories for fabricating custom lab equipment, models, and prototypes.

Art and Fashion

Artists and designers have embraced 3D printing as a medium for artistic expression. It allows for the creation of intricate sculptures, jewelry, and fashion accessories. The ability to produce unique, customized pieces has opened up new possibilities in the world of art and fashion.

Custom Manufacturing

3D printing enables the production of personalized and custom-made products, catering to individual preferences and requirements. This is especially valuable in industries such as consumer goods, where mass customization is a growing trend.

Food Industry

3D printing has even made its way into the food industry. Food printers are capable of creating intricate food items, from chocolate sculptures to customized cakes. This technology has the potential to revolutionize the way food is prepared and served, allowing for greater customization and creativity.

Advantages of 3D Printing

One of the key advantages of 3D printing is its ability to produce complex geometries that cannot be achieved using traditional manufacturing methods. This opens up new design possibilities and allows for the creation of customized, unique products. Additionally, 3D printing offers rapid prototyping capabilities, reducing the time and cost associated with traditional prototyping processes. It also allows for on-demand production, eliminating the need for large-scale manufacturing and inventory storage. Furthermore, 3D printing can reduce material waste as it only uses the exact amount of material needed to build the object, minimizing environmental impact. Lastly, 3D printing has the potential to decentralize production, enabling local manufacturing and reducing reliance on global supply chains.

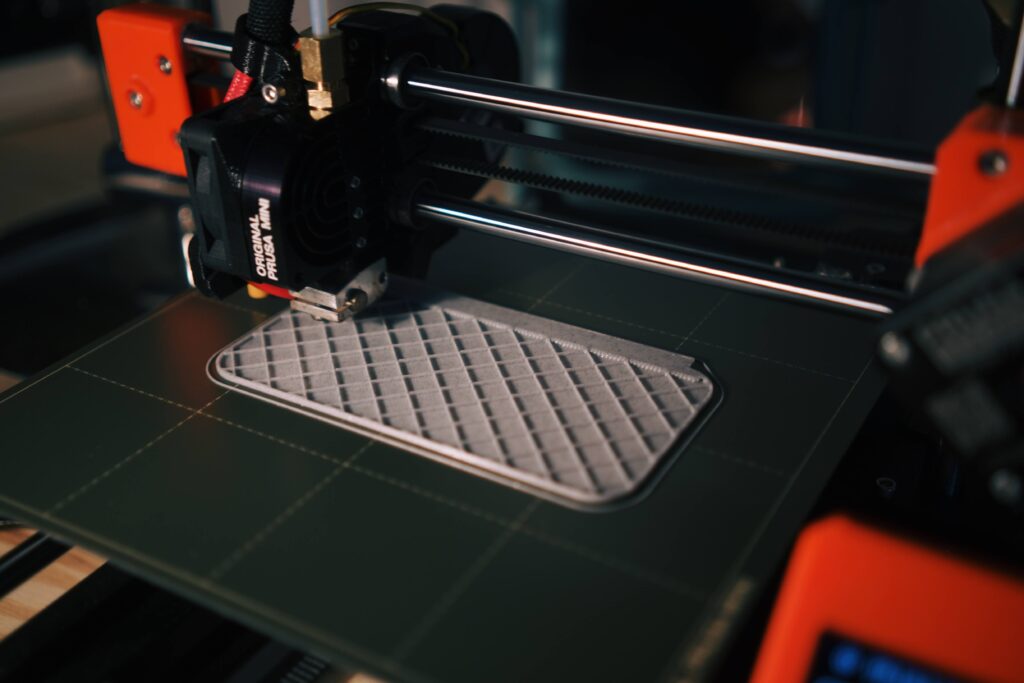

This image is property of images.unsplash.com.

Limitations of 3D Printing

While 3D printing offers numerous advantages, there are also some limitations to consider. One limitation is the speed of the process. 3D printing can be time-consuming, especially when producing large or intricate objects. The choice of materials is another limitation, as not all materials are suitable for 3D printing. Certain materials may have limited availability or may not have the desired properties for specific applications. Additionally, the overall cost of 3D printing can be high, especially when considering the cost of the printer, materials, and post-processing equipment. Finally, the resolution and surface finish of 3D printed objects may not be as high as those achieved through traditional manufacturing methods.

Common 3D Printing Materials

There are various materials available for 3D printing, each with its own properties and applications. Some common materials include:

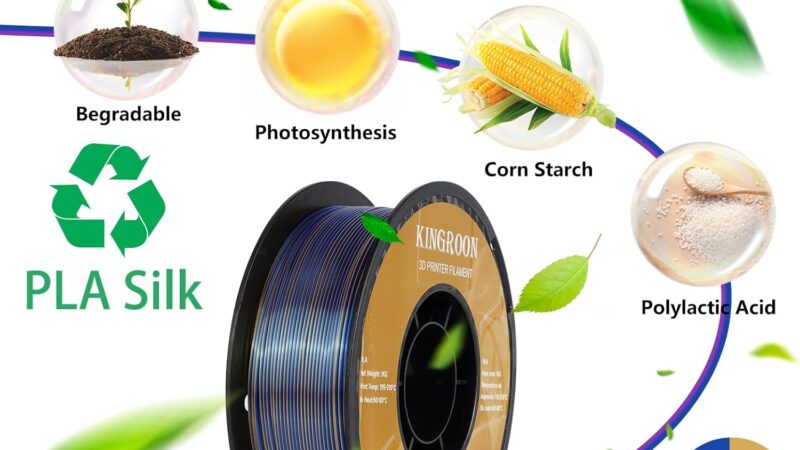

PLA (Polylactic Acid)

PLA is a biodegradable and easy-to-print material that is commonly used in desktop 3D printers. It is ideal for beginners and hobbyists due to its low cost and wide availability. PLA is suitable for a wide range of applications, including prototypes, toys, and household items.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a popular thermoplastic material known for its strength and durability. It is commonly used in the automotive and consumer electronics industries. ABS is more challenging to print than PLA due to its higher printing temperature and increased warping tendencies.

PETG (Polyethylene Terephthalate Glycol)

PETG is a versatile material that combines the strength and durability of ABS with the ease of printing of PLA. It is commonly used in applications that require impact resistance and flexibility, such as mechanical parts and protective casings.

Nylon

Nylon is a strong and flexible material that offers high strength-to-weight ratio and excellent wear resistance. It is commonly used in functional prototypes, tooling, and mechanical parts that require toughness and durability.

Polypropylene (PP)

Polypropylene is a lightweight and chemically resistant material commonly used in packaging, automotive parts, and medical applications. It is challenging to print due to its low adhesion to print beds and high shrinkage.

TPU (Thermoplastic Polyurethane)

TPU is a flexible and elastomeric material that is ideal for producing rubber-like parts, such as gaskets, seals, and footwear. It offers excellent tear and abrasion resistance.

Metals

Metal 3D printing allows for the production of functional, high-strength parts with complex geometries. Common metals used in 3D printing include stainless steel, aluminum, titanium, and nickel alloys. Metal printing often requires specialized equipment and processes.

Ceramics

Ceramic 3D printing enables the production of intricate ceramic objects, such as customized ceramics, prototypes, and dental restorations. It offers high-temperature resistance and excellent chemical stability.

Choosing a 3D Printer

When choosing a 3D printer, there are several factors to consider:

Budget

The cost of 3D printers can vary significantly depending on the technology and capabilities. It is important to determine your budget and consider the long-term costs associated with the printer, such as maintenance and material expenses.

Build Volume

The build volume refers to the maximum size of the object that can be printed. Consider the size of the objects you plan to print and choose a printer with an appropriate build volume.

Print Quality

The print quality is determined by factors such as layer thickness, resolution, and accuracy. Higher print quality often comes at a higher cost, so consider the level of detail you require for your prints.

Printing Speed

The printing speed can vary depending on the technology and printer. Consider the time it takes to print an object and whether speed is a priority for your specific needs.

Filament Compatibility

If you are using a filament-based printer, consider the compatibility of different filament types. Some printers may have limitations on the types of materials they can print with.

Ease of Use

Consider the user-friendliness of the printer, especially if you are a beginner. Look for features such as a user-friendly interface, clear instructions, and reliable customer support.

Connectivity Options

Consider the connectivity options available, such as USB, Wi-Fi, or Ethernet. Some printers also offer wireless printing capabilities, allowing you to print remotely.

Support and Warranty

Check the manufacturer’s warranty and the availability of technical support. A reputable manufacturer should offer reliable support to assist you with any issues or concerns that may arise.

In conclusion, 3D printing is a revolutionary technology that has transformed various industries and opened up new possibilities for creativity and innovation. From rapid prototyping to customized manufacturing, 3D printing offers numerous advantages, including the ability to create complex geometries, reduce material waste, and accelerate product development cycles. While there are limitations to consider, such as speed and cost, the wide range of available materials and printer options make 3D printing accessible and applicable to a diverse range of applications. Whether you are a hobbyist, an engineer, or a designer, 3D printing offers endless opportunities to bring your ideas to life.