Revolutionary 3D Printed Robotic Arm

Hello there! In this article, we will be discussing the incredible technology behind the 3D printed robotic arm. You’ll learn about how this revolutionary arm is changing the game in robotics and manufacturing, as well as the benefits it brings to various industries. We’ll also explore the process of 3D printing and how it is used to create these robotic arms, making them affordable and customizable. Stay tuned to discover the fascinating world of 3D printed robotic arms and how they are shaping our future!

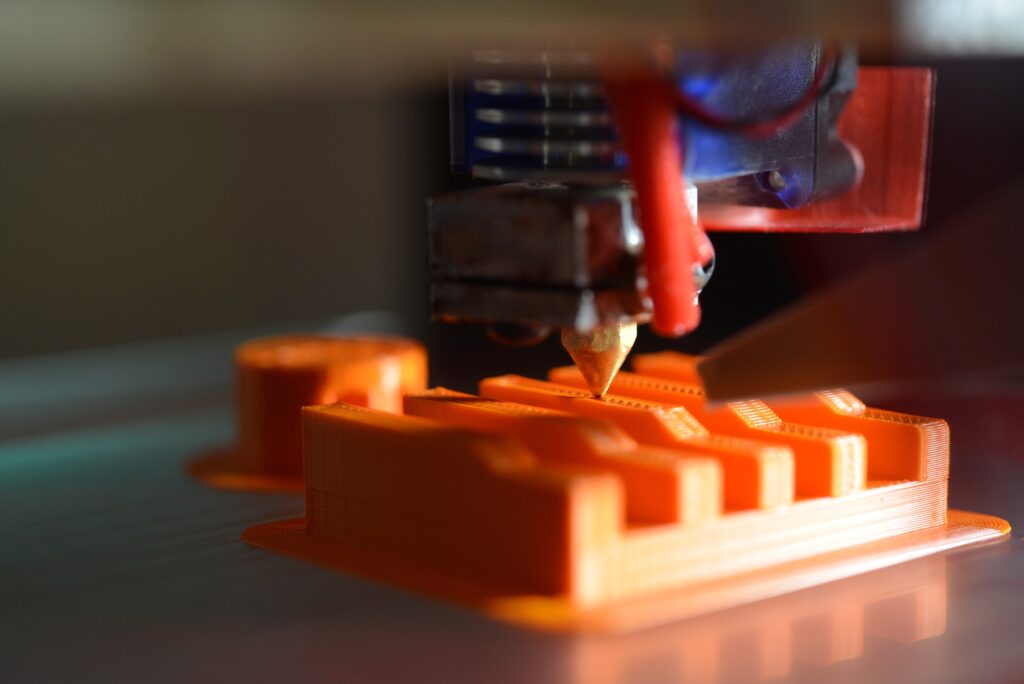

This image is property of images.unsplash.com.

Development and Advancements of 3D Printed Robotic Arms

Introduction to 3D Printed Robotic Arms

In recent years, the field of robotics has witnessed significant advancements, particularly in the development of 3D printed robotic arms. These innovative creations have revolutionized various industries by providing customizable and flexible solutions. This article aims to explore the evolution, design, applications, integration of artificial intelligence, benefits and limitations, safety measures, and future trends of 3D printed robotic arms. It will also delve into the ethical considerations and social impacts associated with this cutting-edge technology.

Evolution of Robotic Arms in Manufacturing

Robotic arms have been an integral part of manufacturing processes for several decades. Initially, they were bulky and expensive machines that were typically limited in their range of motion and adaptability. However, with the advent of 3D printing technology, the design and engineering of robotic arms have undergone a transformation. The ability to create complex structures with additive manufacturing has paved the way for lighter, more compact, and efficient robotic arms.

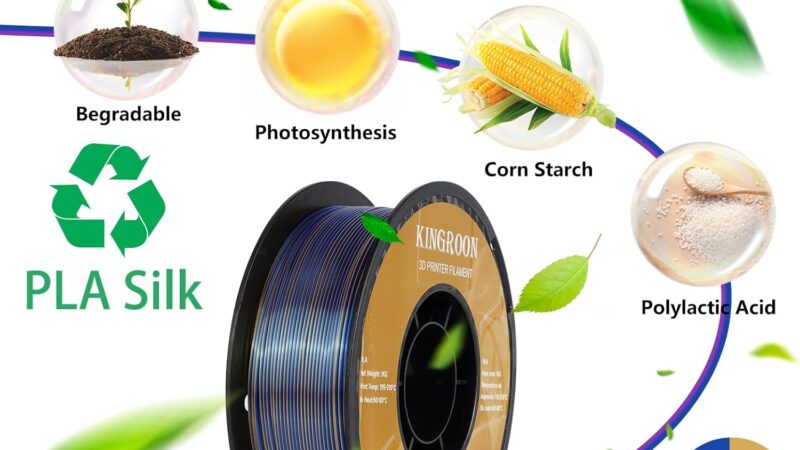

Innovations in 3D Printing Technology for Robotic Arms

The advancements in 3D printing technology have played a crucial role in enhancing the capabilities of robotic arms. Manufacturers can now produce intricate and customized components with ease, reducing the need for complex and expensive tooling. This has led to increased efficiency, lower production costs, and improved overall performance of robotic arms. Innovations such as multi-material printing and high-resolution printing have further expanded the possibilities in creating intricate and functional designs.

Design and Engineering of 3D Printed Robotic Arms

Structural Components of 3D Printed Robotic Arms

The design and engineering of 3D printed robotic arms involve the careful consideration of various structural components. These components include the base, links, joints, and end effectors. 3D printing enables the creation of lightweight yet sturdy components, allowing for improved speed, precision, and payload capacity. The use of materials such as carbon fiber, titanium, and nylon ensures the strength and durability necessary for demanding tasks.

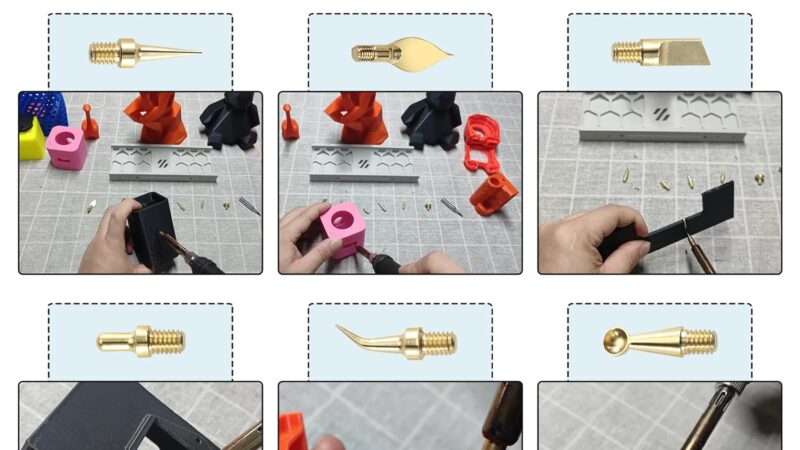

Integration of Motors and Actuators

Motors and actuators are essential for the movement and control of robotic arms. 3D printing technology allows for the seamless integration of these components, reducing the need for additional assembly and improving overall efficiency. Designers can optimize the placement and orientation of motors and actuators to maximize performance and minimize space requirements. This integration also enables smoother and more precise movements, resulting in enhanced productivity.

Sensors and Feedback Systems for Enhanced Control

To ensure accurate and safe operations, 3D printed robotic arms are equipped with sensors and feedback systems. These sensors provide vital information on position, force, and torque to enable real-time adjustments and control. 3D printing offers the flexibility to incorporate these sensors directly into the structure of the robotic arm, eliminating the need for additional wiring and external sensing devices. This integration enhances the reliability and responsiveness of the robotic arm, improving its overall functionality.

Applications and Industries Benefiting from 3D Printed Robotic Arms

Automotive Manufacturing

The automotive industry has embraced the use of 3D printed robotic arms to streamline production processes. These robotic arms can be configured to handle various tasks, such as assembling components, painting, and welding. The customizability and flexibility of 3D printed robotic arms enable manufacturers to adapt to changing production demands quickly. Furthermore, the integration of artificial intelligence algorithms allows for enhanced decision-making capabilities, resulting in improved efficiency and quality control.

Aerospace Industry

The aerospace industry heavily relies on precision and efficiency in its manufacturing processes. 3D printed robotic arms have been instrumental in meeting these requirements. From assembling intricate aircraft components to handling delicate materials, these robotic arms can perform a wide range of tasks with precision and repeatability. The ability to produce lightweight yet robust components through 3D printing technology contributes to the overall weight reduction of aircraft, leading to improved fuel efficiency and performance.

Medical and Healthcare Sector

In the medical and healthcare sector, 3D printed robotic arms have proven to be invaluable tools. They are used in various applications, including surgical procedures, prosthetic limb manufacturing, and rehabilitation. The customizability of these robotic arms allows for tailored solutions that cater to specific patient needs. Moreover, the integration of sensors and artificial intelligence enables precise and delicate movements, ensuring patient safety and improving surgical outcomes.

Customizability and Flexibility of 3D Printed Robotic Arms

Tailoring Robotic Arm Designs for Specific Tasks

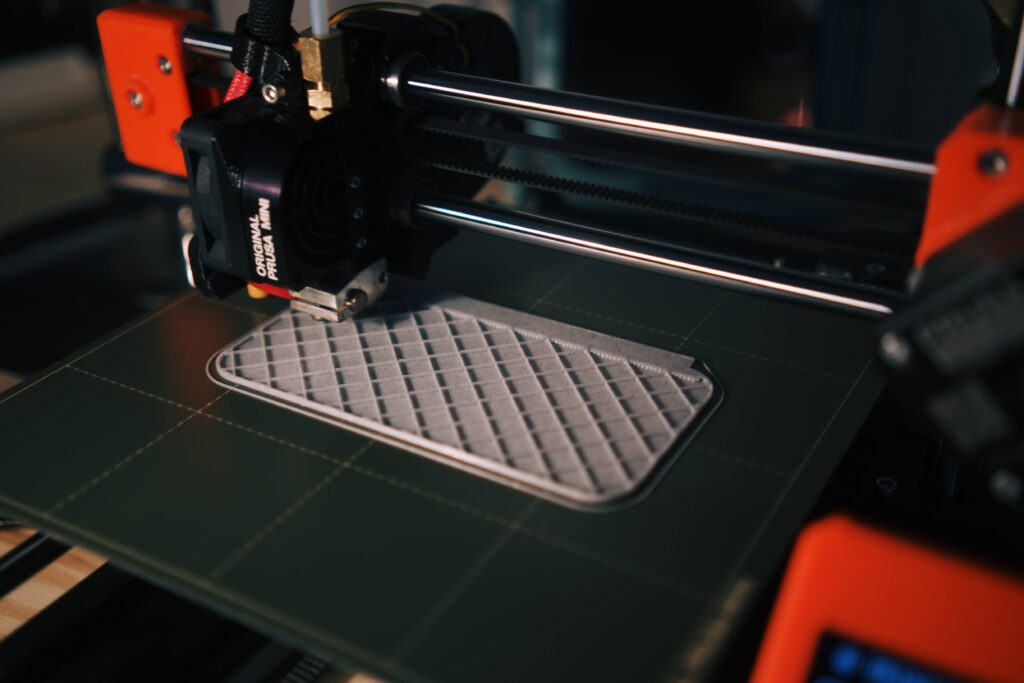

One of the key advantages of 3D printed robotic arms is the ability to tailor their designs for specific tasks. Manufacturers can optimize the structure, size, and configuration of the robotic arms to meet the requirements of a particular application. This level of customization ensures that the robotic arm performs optimally, resulting in improved productivity and efficiency. Whether it is a small-scale assembly line or a complex industrial application, 3D printed robotic arms can be designed and manufactured to suit the specific needs of the task at hand.

Adaptability to Various Environments and Workspaces

3D printed robotic arms are highly adaptable to various environments and workspaces. Unlike traditional robotic arms, which often require significant modifications to fit into different settings, 3D printed robotic arms can be easily configured and modified. This flexibility allows businesses to adapt quickly to changing production needs and optimize their operations. The ability to reconfigure and relocate robotic arms efficiently results in cost savings and streamlined workflows.

On-Demand Manufacturing Solutions

With 3D printing technology, businesses can benefit from on-demand manufacturing solutions. The ability to rapidly prototype and manufacture components allows for shorter lead times and reduced inventory costs. This is particularly beneficial for small businesses and startups that require flexible and cost-effective manufacturing solutions. 3D printed robotic arms enable these companies to remain competitive by offering agile and efficient manufacturing processes.

This image is property of images.unsplash.com.

Integration of Artificial Intelligence in 3D Printed Robotic Arms

Machine Learning Algorithms for Improved Performance

The integration of artificial intelligence (AI) algorithms enhances the capabilities of 3D printed robotic arms. Machine learning algorithms enable robotic arms to acquire knowledge and improve their performance over time. By analyzing vast amounts of data and making accurate predictions, these algorithms optimize the robotic arm’s movements, resulting in increased productivity and efficiency. The continuous learning capability allows the robotic arms to adapt to changing tasks and environments, making them versatile and intelligent tools.

Object Recognition and Manipulation

Object recognition and manipulation are vital skills for robotic arms in various industries. Through the integration of AI and computer vision technologies, 3D printed robotic arms can identify objects, determine their characteristics, and manipulate them accordingly. This capability allows for precise and efficient handling of objects, reducing the risk of damage and improving overall productivity. The combination of object recognition and manipulation with 3D printed robotic arms opens up new possibilities for automation across multiple sectors.

Collaborative Robotics with Human Interaction

Collaborative robotics, also known as cobots, involve the interaction between humans and robots. 3D printed robotic arms are well-suited for collaborative applications, thanks to their flexibility, lightweight design, and advanced control systems. With the assistance of AI algorithms, these robotic arms can detect and respond to human presence, ensuring safe and efficient collaboration. This collaboration not only improves productivity but also reduces the risk of workplace accidents, making it a win-win situation for both humans and robots.

Benefits and Limitations of 3D Printed Robotic Arms

Cost Reduction and Time Efficiency in Production

The use of 3D printed robotic arms offers significant benefits in terms of cost reduction and time efficiency in production. The ability to manufacture complex components in-house eliminates the need for outsourcing and reduces associated costs. Additionally, the shortened manufacturing cycle resulting from 3D printing technology translates to faster product development and reduced time to market. These cost and time-saving advantages contribute to the overall competitiveness of businesses utilizing 3D printed robotic arms.

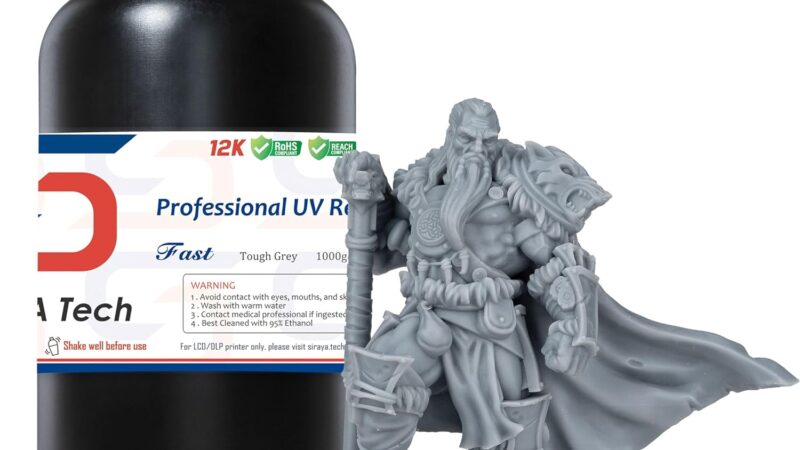

Enhanced Precision and Accuracy

Accurate and precise movements are paramount in various applications, such as assembly lines and surgical procedures. 3D printed robotic arms excel in providing enhanced precision and accuracy. The combination of lightweight yet rigid materials, advanced control systems, and integration of sensors allows for minute and delicate movements. The high level of precision and accuracy significantly reduces errors and improves overall quality control, resulting in increased productivity and customer satisfaction.

Challenges and Constraints in Material Selection

Although 3D printing technology offers a wide range of material options, selecting the suitable material for specific applications can be challenging. The choice of material depends on factors such as strength, durability, and resistance to wear and tear. While materials like carbon fiber and titanium offer exceptional strength, they may be more expensive and difficult to 3D print. On the other hand, materials like thermoplastics provide cost-effective options but may have limitations in terms of strength and heat resistance. Careful consideration of material properties is crucial to ensure that 3D printed robotic arms perform optimally in their intended applications.

This image is property of images.unsplash.com.

Safety Measures and Regulations for 3D Printed Robotic Arms

Risk Assessment and Mitigation Strategies

Safety is a paramount concern when it comes to the operation of 3D printed robotic arms. Proper risk assessment and mitigation strategies should be in place to identify potential hazards and implement appropriate control measures. Regular maintenance and inspection of the robotic arms are crucial to ensure their safe and reliable operation. Further, comprehensive training programs for operators and personnel involved in working with these robotic arms are essential to minimize the risk of accidents and injuries.

Compliance with Industrial Standards

Compliance with industrial standards is imperative to ensure the safe and reliable operation of 3D printed robotic arms. These standards often cover aspects such as electrical safety, electromagnetic compatibility, and functional safety. Adhering to these standards ensures that the robotic arms meet stringent quality control requirements and minimize the risk of malfunctions or accidents. Manufacturers and operators must stay updated with the latest industry standards and regulations to maintain a high level of safety in their operations.

Ensuring Operator Safety

The safety of operators working with 3D printed robotic arms is of utmost importance. Adequate safety measures, such as emergency stop buttons, protective barriers, and safety interlocks, should be incorporated into the design of the robotic arms. Additionally, thorough training on proper handling and operation of the robotic arms should be provided to operators. This training should include information on potential hazards, safety protocols, and emergency procedures. By prioritizing operator safety, businesses can mitigate risks and create a safer working environment.

Future Trends and Potential of 3D Printed Robotic Arms

Advancements in Materials and Printing Techniques

The future of 3D printed robotic arms holds exciting possibilities, particularly in the advancement of materials and printing techniques. Ongoing research and development efforts continue to expand the range of materials that can be 3D printed, resulting in improved performance and cost-effectiveness. Furthermore, advancements in printing techniques, such as multi-material printing and continuous printing, will further enhance the capabilities of robotic arm manufacturing. These innovations will pave the way for even lighter, stronger, and more versatile 3D printed robotic arms.

Integration with Internet of Things (IoT) Systems

The integration of 3D printed robotic arms with Internet of Things (IoT) systems represents another significant trend for the future. IoT enables seamless communication and data exchange between interconnected devices. By connecting robotic arms to IoT systems, businesses can collect real-time data on performance, maintenance needs, and efficiency. This data-driven approach allows for predictive maintenance, optimized performance, and continuous improvement of robotic arm operations.

Exploration of Collaborative Swarm Robotics

Collaborative swarm robotics involves the coordination and cooperation of multiple robotic systems to perform tasks collectively. The application of this concept to 3D printed robotic arms holds immense potential for increased productivity, efficiency, and adaptability. By intelligently coordinating the movements and actions of multiple robotic arms, complex tasks can be accomplished more quickly and effectively. The exploration of collaborative swarm robotics in the context of 3D printed robotic arms promises new avenues for automation, particularly in industries where multiple tasks need to be carried out simultaneously.

Ethical Considerations and Social Impacts

Potential Job Displacement and Workforce Skills

The adoption of 3D printed robotic arms in various industries raises concerns about potential job displacement and the need for a skilled workforce. While robotic automation has the potential to replace certain manual tasks, it also creates opportunities for upskilling and reskilling. As jobs evolve and tasks become more automated, the workforce will need to acquire new skills to remain valuable in the employment market. It is crucial for businesses and policymakers to invest in training and education programs to ensure a smooth transition and minimize the impact on workers.

Ethical Usage of Autonomous Robotic Arms

As 3D printed robotic arms become more advanced and autonomous, ethical considerations regarding their usage become increasingly important. Clear guidelines and regulations must be established to ensure responsible and ethical practices. This includes considerations such as respecting privacy, preventing misuse or abuse of robotic arms, and addressing potential risks associated with autonomous decision-making capabilities. By prioritizing ethical usage, businesses can foster trust and maintain a positive societal impact.

Addressing Societal Concerns

The widespread adoption of 3D printed robotic arms may raise concerns within society regarding potential job loss, economic inequalities, and societal impact. It is essential for businesses and policymakers to engage in open dialogues and address these concerns proactively. This includes initiatives such as job retraining programs, economic and social policies to mitigate inequalities, and transparent communication about the benefits and limitations of 3D printed robotic arms. By addressing these concerns head-on, businesses and policymakers can foster public acceptance and ensure a smooth integration of this revolutionary technology.

Conclusion

The development and advancements of 3D printed robotic arms have brought about a revolution in various industries. Through precise engineering, integration of artificial intelligence, and continuous innovation, these robotic arms have transformed manufacturing processes, improved efficiency, and opened up new possibilities for automation. However, with these advancements come ethical considerations and social impacts that must be addressed responsibly. The future of 3D printed robotic arms holds immense potential, from advancements in materials and printing techniques to the exploration of collaborative swarm robotics. By leveraging these advancements while considering their implications, businesses and society can fully embrace the revolutionary potential of 3D printed robotic arms.