Revolutionizing Construction: The Rise of 3D Printed Concrete Houses

In this article, you will learn about the latest trend that is revolutionizing the construction industry: 3D printed concrete houses. We will explore how this innovative technology is changing the way houses are built and discuss the benefits it offers. From increased efficiency and cost-effectiveness to design flexibility and sustainability, you will discover why 3D printed concrete houses are gaining popularity. So, join us as we delve into this fascinating topic and uncover the future of construction!

Introduction

With the rapid advancement of technology, the construction industry is embracing innovative methods to create efficient and sustainable housing solutions. One such technology that has gained immense popularity in recent years is 3D printing. You may have heard of 3D printing being used for creating small objects or parts, but did you know that it can now be used to build entire houses? That’s right, 3D printed concrete houses are revolutionizing the world of construction, offering numerous advantages over traditional building methods.

The growing popularity of 3D printing technology

From medical devices to automotive parts, 3D printing has been widely adopted across various industries. However, it is in the construction sector where this technology is making one of the biggest impacts. The ability to construct houses layer by layer using a 3D printer has opened up a whole new realm of possibilities for architects, engineers, and builders.

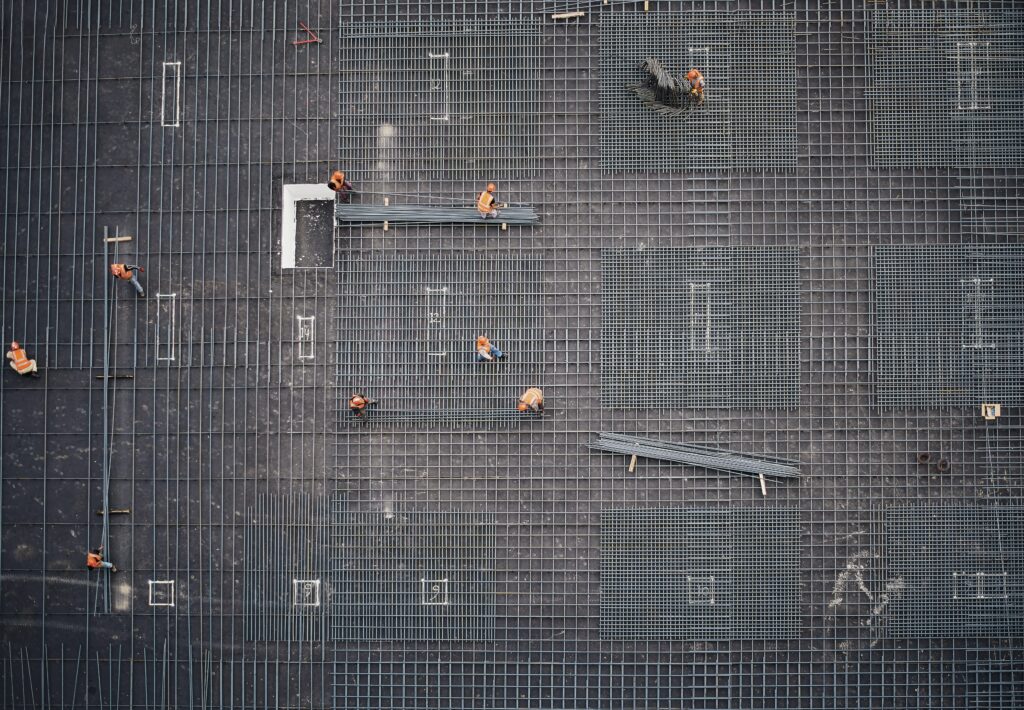

This image is property of images.unsplash.com.

The emergence of 3D printed concrete houses

Traditional construction methods often involve extensive manual labor, which can be time-consuming and costly. 3D printed concrete houses, on the other hand, save both time and money. By using a specially designed 3D printer and a mixture of concrete, these houses can be built rapidly and with greater precision.

Advantages of 3D Printed Concrete Houses

Cost-effectiveness and reduced labor

One of the major advantages of 3D printed concrete houses is their cost-effectiveness. Since the construction process is automated, the need for a large workforce is significantly reduced. There is also a reduction in material waste, as the 3D printer applies the concrete in a precise manner, minimizing the amount of excess material.

Design flexibility and customization options

Another benefit of 3D printed concrete houses is the design flexibility they offer. Traditional construction methods often limit architectural possibilities, but with 3D printing, intricate designs and complex shapes can be easily achieved. This allows architects to experiment with innovative designs and create unique structures that were previously unimaginable.

Faster construction process

Time is crucial in the construction industry, and 3D printed concrete houses excel in this area. Compared to traditional construction methods, the speed of 3D printing is unparalleled. The layer-by-layer printing process is incredibly efficient, allowing houses to be built in a matter of days or weeks, rather than months.

Improved sustainability and reduced waste

Sustainability is a pressing issue globally, and the construction industry has a significant impact on the environment. 3D printing offers a more sustainable alternative by minimizing waste and reducing the carbon footprint. Traditional construction methods often produce excessive waste during the building process, but 3D printing eliminates this issue by utilizing the concrete precisely.

This image is property of images.unsplash.com.

Technology and Process

3D printing techniques and machinery

The technology behind 3D printing houses involves the use of large-scale, robotic 3D printers. These printers are equipped with special nozzles that extrude concrete layer by layer, following a digital blueprint. The printers are programmed to move in a controlled manner, ensuring accurate placement of the concrete and the formation of the desired structure.

Selection and preparation of concrete materials

Choosing the right type of concrete is crucial for the success of 3D printed houses. The concrete must have the right consistency and be able to flow smoothly through the printer nozzles. Special additives or reinforcements may be added to enhance the strength and durability of the printed structure.

Layer-by-layer printing process

To create a 3D printed concrete house, the printer starts by depositing a thin layer of concrete onto a build platform. Once the first layer is complete, the printer moves up a level, and another layer is added on top of the previous one. This process is repeated until the entire house is built, layer by layer. The result is a solid and structurally sound concrete house, with all the necessary features and details.

Quality and Durability

Strength and structural integrity of 3D printed concrete

One question that often arises when discussing 3D printed concrete houses is their strength and structural integrity. Extensive testing and certification procedures have been conducted to ensure that these houses meet and exceed industry standards. In fact, 3D printed concrete houses have been found to have superior strength compared to traditionally built houses. The layer-by-layer printing process allows for precise placement of the concrete, resulting in a more uniform and reinforced structure.

Testing and certification procedures

To ensure the quality and durability of 3D printed concrete houses, rigorous testing and certification procedures have been implemented. These procedures involve structural testing, assessing material properties, and analyzing the overall performance of the printed structure. Once the houses pass these tests, they are certified as safe and durable.

Longevity and resistance to natural disasters

One of the advantages of 3D printed concrete houses is their resilience to natural disasters. The use of concrete as the primary material provides a solid and sturdy structure that can withstand earthquakes, hurricanes, and other extreme weather events. This makes 3D printed concrete houses an ideal solution for areas prone to natural disasters.

This image is property of images.unsplash.com.

Architectural Possibilities

Innovative shapes and forms

The design possibilities offered by 3D printed concrete houses are truly remarkable. Architects are no longer limited by the constraints of traditional construction methods. Complex shapes, intricate designs, and even curves can be easily achieved with 3D printing. This opens up a whole new world of architectural possibilities, allowing for truly unique and aesthetically pleasing structures.

Complex detailing and intricate designs

In addition to innovative shapes, 3D printed concrete houses also enable complex detailing and intricate designs. The precision of the 3D printer allows for the creation of fine details that would be challenging or impossible to achieve with traditional construction methods. This level of detail can greatly enhance the overall aesthetics and appeal of the house.

Integration of utility systems within printed structures

Another advantage of 3D printed concrete houses is the ability to integrate utility systems within the printed structure. During the printing process, channels can be created within the walls to accommodate electrical wiring, plumbing, and other utility systems. This not only reduces the need for additional construction work but also enhances the overall efficiency and functionality of the house.

Challenges and Limitations

Material limitations and properties

One of the challenges faced by 3D printed concrete houses is the limited availability of suitable concrete materials. The concrete used for 3D printing must have specific properties, such as the ability to flow smoothly through the printer nozzles and set quickly. Additionally, the strength and durability of 3D printed concrete houses still need to be further studied and improved.

Precision and accuracy in printing

Achieving high precision and accuracy in 3D printing can be challenging, especially when constructing large-scale structures like houses. Small errors or imperfections in the printing process can result in structural weaknesses or aesthetic imperfections. Ongoing research and development efforts are focused on enhancing the precision and accuracy of 3D printed concrete houses.

Regulations and building codes

As with any new technology, there are regulatory challenges to overcome. Building codes and regulations may need to be updated to accommodate the use of 3D printed concrete houses. Additionally, the certification and approval processes for these houses may need to be standardized to ensure their quality and safety.

Acceptance and public perception

The acceptance and perception of 3D printed concrete houses among the general public can also be a challenge. Many people are still unfamiliar with this technology and may have reservations about living in a house that was “printed”. However, as more 3D printed houses are built and their benefits become evident, public acceptance is expected to grow.

Current Projects and Initiatives

Prominent 3D printed concrete house projects worldwide

Numerous 3D printed concrete house projects have already been completed or are currently underway around the world. From the first 3D printed house in China to the world’s largest 3D printed concrete building in Dubai, these projects showcase the immense potential of this technology. Some projects are focused on affordable housing, while others aim to push the boundaries of architectural design.

Collaborative efforts and research advancements

Governments, universities, and private companies are collaborating on research initiatives to further advance the technology of 3D printed concrete houses. These collaborations aim to enhance the materials used, refine the printing process, and explore new applications for this technology. The collective efforts of these entities are driving the progress and development of 3D printed concrete houses.

Economic and Social Impact

Affordable housing solutions

One of the most significant impacts of 3D printed concrete houses is their potential to provide affordable housing solutions. Traditional construction methods can be costly, making it challenging for low-income individuals and families to find suitable housing. 3D printing technology has the potential to significantly reduce construction costs, making housing more affordable and accessible to a larger portion of the population.

Job creation and employment opportunities

The adoption of 3D printed concrete houses also creates new job opportunities and stimulates economic growth. While some traditional construction jobs may be replaced by automated 3D printing processes, new roles will emerge in areas such as 3D printer operation, maintenance, and design. This technology fosters innovation and entrepreneurship in the construction industry, driving employment and economic development.

Urbanization and housing demands

As the global population continues to grow, the demand for housing in urban areas is rising. 3D printed concrete houses can play a crucial role in addressing this demand by providing a quick and efficient housing solution. The speed and cost-effectiveness of 3D printing can help meet the housing needs of rapidly growing urban populations.

Environmental Considerations

Reduced carbon footprint

Sustainability is a key concern in the construction industry, and 3D printed concrete houses offer a more environmentally friendly alternative to traditional construction methods. The precise application of concrete reduces material waste, minimizing the carbon footprint associated with construction. Additionally, the use of concrete as the primary material can contribute to lower energy consumption during the lifecycle of the house.

Energy efficiency of 3D printed construction

3D printed concrete houses can also be designed to maximize energy efficiency. The precise construction process allows for better insulation, reducing energy consumption for heating and cooling. Additionally, the integration of utility systems within the printed structure can further enhance energy efficiency by optimizing the flow of electricity and water.

Recyclability and waste management

The use of 3D printing for construction also opens up possibilities for recycling and waste management. Excess or leftover concrete can be recycled and reused in future printing projects, reducing the need for new raw materials. Additionally, 3D printing can minimize the amount of construction waste generated, contributing to more sustainable construction practices.

Conclusion

The rise of 3D printed concrete houses is revolutionizing the construction industry. The cost-effectiveness, design flexibility, and quicker construction process make this technology an attractive alternative to traditional building methods. While there are still challenges to overcome in terms of materials and precision, ongoing research and development are driving advancements in 3D printing technology. The potential economic, social, and environmental impacts of 3D printed concrete houses are immense, making them a promising solution for the future of housing. As acceptance and awareness of this technology grow, we can expect to see an even greater transformation in the way we build and live in houses.