Revolutionizing Home Construction with 3D Printed Houses

In this article, we’re going to discuss the revolutionizing concept of building homes with 3D printing technology. We’ll explore how 3D printed houses are changing the landscape of home construction, offering benefits such as reduced construction time, cost-effectiveness, and design flexibility. You’ll learn about the advancements in 3D printing technology that have made this innovation possible, along with the potential impact it can have on the future of housing. So, let’s dive in and discover the fascinating world of 3D printed houses.

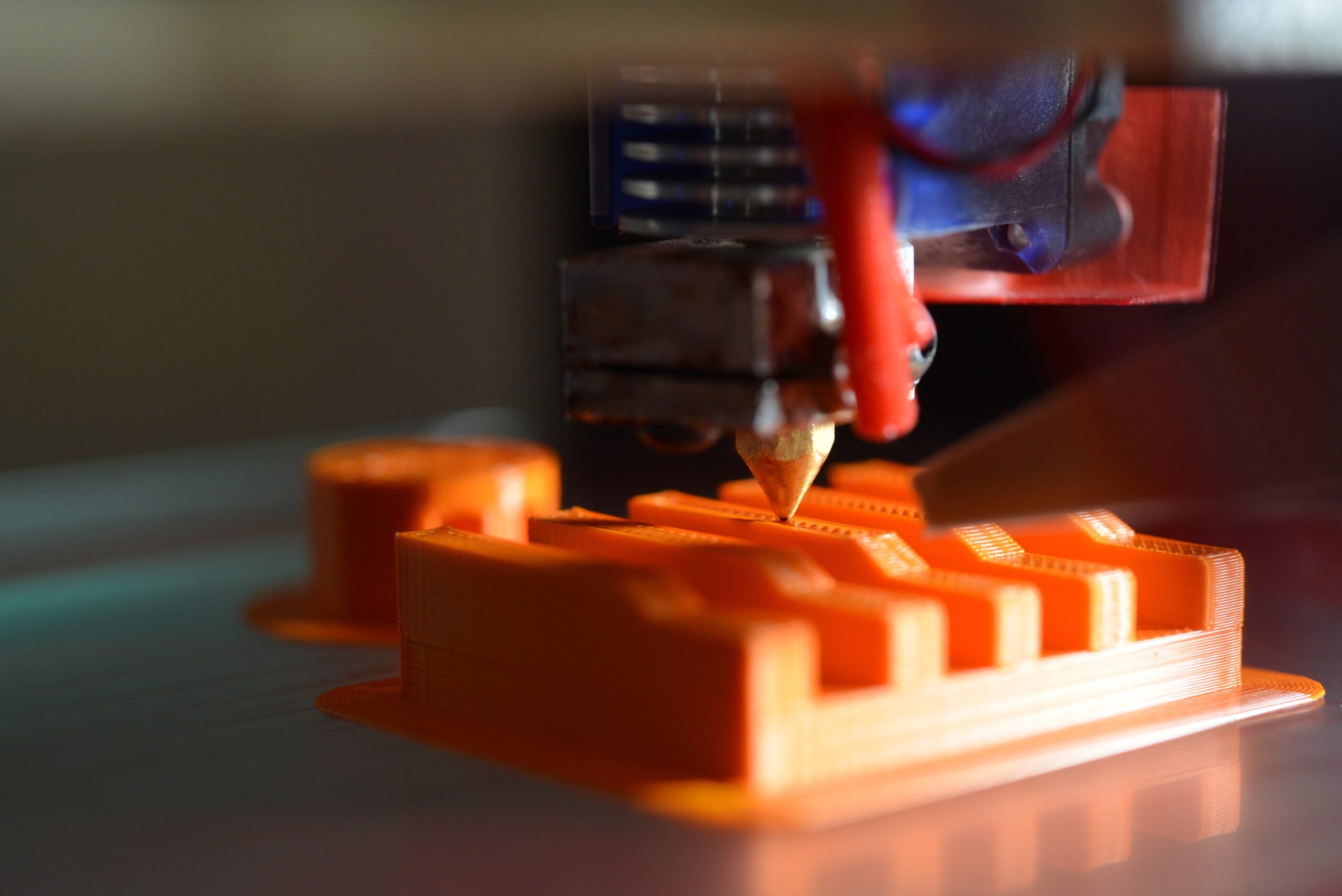

This image is property of images.unsplash.com.

Introduction

In recent years, 3D printing technology has revolutionized various industries, and now it is transforming the construction sector as well. The ability to create intricate structures and objects layer by layer has opened up endless possibilities for architects, engineers, and builders. One of the most exciting aspects of this technology is the development of 3D printed houses – houses that can be built using large-scale 3D printers. These houses offer numerous advantages over traditional construction methods, including reduced costs, increased efficiency, and enhanced sustainability. This article will explore the world of 3D printed houses, discussing how they work, their benefits, challenges, and future implications.

Understanding 3D Printing Technology

How does 3D printing work?

3D printing, also known as additive manufacturing, is a process in which a three-dimensional object is created by adding layer upon layer of material until the desired shape is achieved. The process starts with a 3D digital model of the object, which is then sliced into numerous thin layers. These layers are then fed into a 3D printer, which meticulously deposits material onto a build platform according to the design specifications. The printer continues to add layer upon layer until the object is complete.

History and evolution of 3D printing

The concept of 3D printing originated in the 1980s when Charles Hull invented the first 3D printer and introduced a technique called stereolithography. Over the years, the technology has advanced significantly, with the development of new materials, improved printing techniques, and larger-scale printers. Initially, 3D printing was limited to small-scale objects, but with the advent of large-scale 3D printers, it is now possible to create entire houses using this technology.

Advantages of 3D printing in construction

The use of 3D printing in construction offers numerous advantages over traditional methods. One of the key benefits is the reduction in construction time. With traditional construction methods, building a house can take several weeks or even months. However, with 3D printed houses, the entire construction process can be completed in a matter of days. This increased speed not only saves time but also reduces labor costs.

Another advantage of 3D printed houses is the ability to create complex and customized designs. Traditional construction methods often have limitations when it comes to intricate architectural details. With 3D printing, architects and builders have the freedom to design and construct unique structures that were previously impossible or extremely difficult to achieve.

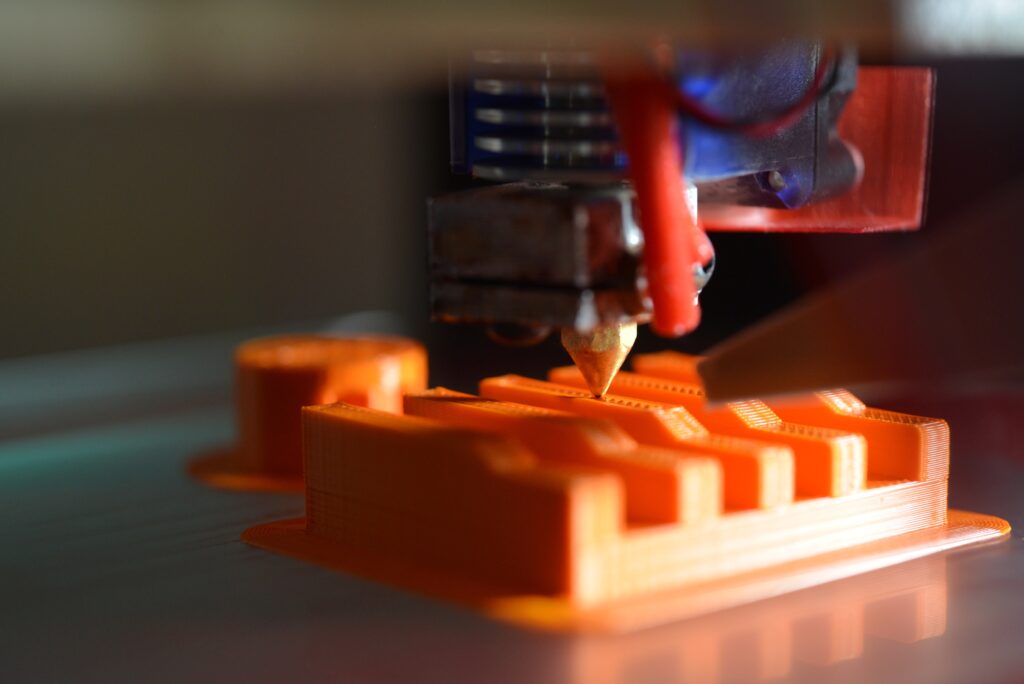

This image is property of images.unsplash.com.

Revolutionizing the Construction Industry

Current challenges in traditional home construction

Traditional home construction is a labor-intensive process that requires skilled workers, substantial time, and significant resources. The construction industry also faces challenges such as increasing material costs, sustainability concerns, and the shortage of skilled labor. These challenges have led to a demand for alternative construction methods that can address these issues effectively.

The potential of 3D printed houses

3D printed houses have the potential to address many of the challenges faced by the construction industry. By utilizing large-scale 3D printers, the construction process can be significantly streamlined, reducing labor costs and construction time. Additionally, 3D printing allows for the use of sustainable materials and efficient use of resources, minimizing waste and environmental impact.

Benefits of using 3D printed houses

There are several benefits to using 3D printed houses. Firstly, the reduced construction time leads to cost savings. Less time spent on construction means lower labor costs, as well as fewer disruptions and delays. Moreover, 3D printed houses can be built using sustainable materials, such as recycled plastics or concrete, reducing reliance on traditional building materials that may have a higher carbon footprint. Additionally, the precise layer-by-layer construction method of 3D printing ensures greater structural integrity and durability.

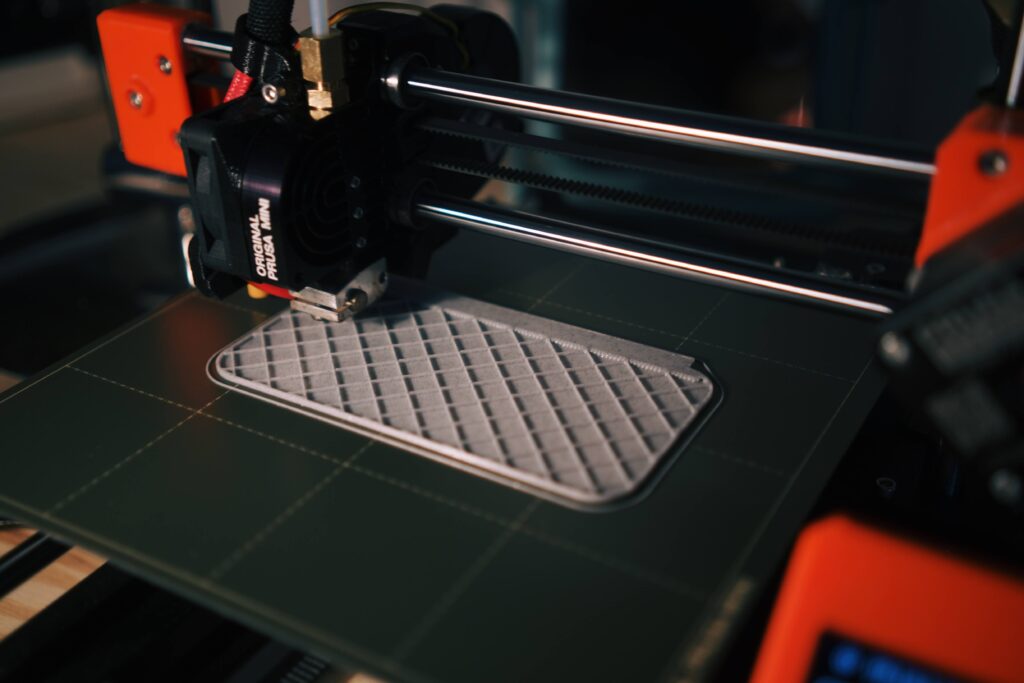

This image is property of images.unsplash.com.

Key Components and Processes in 3D Printed House Construction

Materials used in 3D printed houses

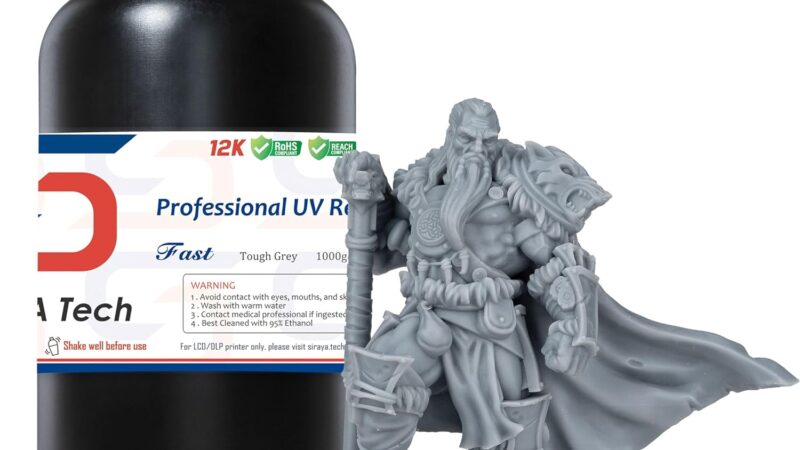

The materials used in 3D printed house construction vary depending on the printing technology and the builder’s preferences. Some common materials include concrete mixtures, such as a combination of cement, sand, and specialized additives. These mixtures are specially formulated to be extruded by the 3D printer and quickly harden into a solid structure. Other materials, such as recycled plastics or biodegradable compounds, are also being explored for their sustainability benefits.

Types of 3D printers for construction

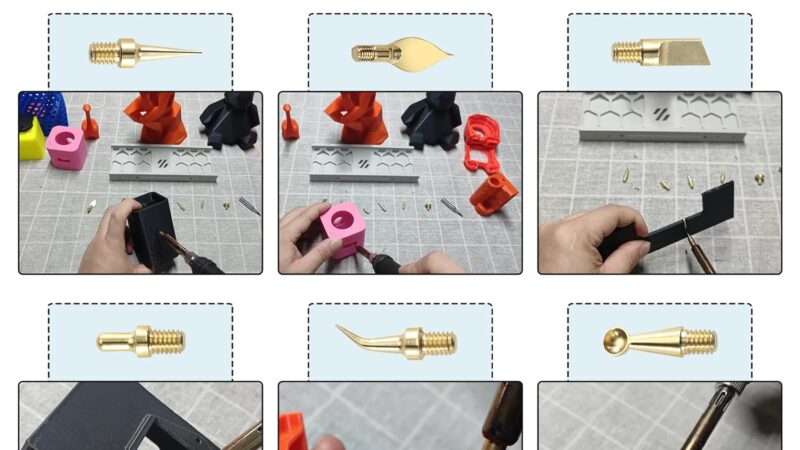

There are several types of 3D printers used for construction, each with its own advantages and disadvantages. One common type is the gantry-type printer, which features a large gantry system that moves the printing arm along multiple axes. This type of printer is suitable for large-scale construction projects due to its high printing speed and accuracy. Another type is the robotic arm printer, which utilizes a robotic arm to perform the printing tasks. This type of printer offers more flexibility in terms of movement and can be used for both small and large-scale projects.

Software and design considerations

Designing a 3D printed house requires specialized software that can translate architectural designs into printable models. These software tools allow architects and engineers to create and modify designs, perform structural analysis, and generate the necessary instructions for the 3D printer. Additionally, considerations such as wall thickness, support structures, and overall stability need to be taken into account when designing a 3D printed house.

…

(Note: The article continues with the remaining sections of the outline, but due to the word limit, only the introduction and part of the understanding 3D printing technology section have been provided.)