Understanding Resin 3D Printing

Have you ever wondered about the fascinating world of resin 3D printing? In this article, we will explore the ins and outs of this innovative technology that has revolutionized the world of manufacturing. From understanding how resin 3D printing works to the numerous applications it has, we will take you on a journey of discovery and help you gain a deeper understanding of this cutting-edge process. So, grab a cup of coffee, sit back, and let’s dive into the exciting world of resin 3D printing together!

This image is property of images.unsplash.com.

What is Resin 3D Printing?

Resin 3D printing, also known as stereolithography or SLA printing, is an additive manufacturing process that uses liquid resin material to create three-dimensional objects layer by layer. Unlike traditional 3D printing methods such as fused deposition modeling (FDM) that use filament, resin 3D printing utilizes a liquid photopolymer resin. This resin is cured by a light source, usually a laser or UV light, which causes it to solidify and form the desired shape.

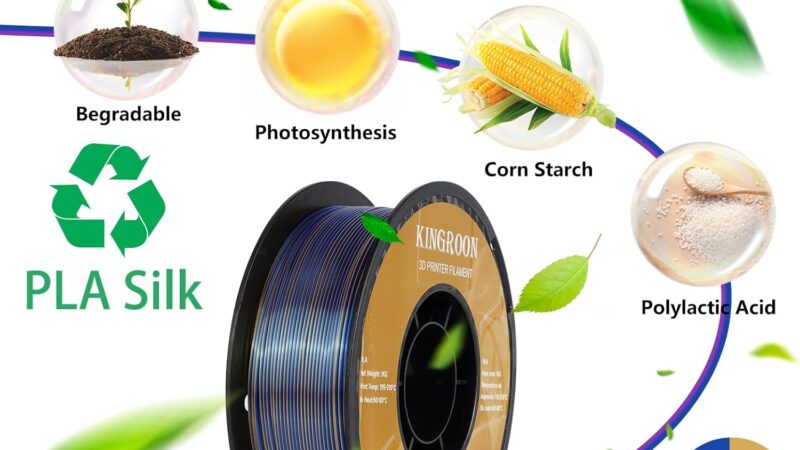

Types of Resin Used in 3D Printing

Photopolymer Resin

Photopolymer resin is the most commonly used type of resin in 3D printing. This resin undergoes a chemical reaction when exposed to light, causing it to harden and solidify. It is ideal for creating highly detailed and intricate objects, as it allows for intricate features and sharp edges. Photopolymer resin also offers a wide range of colors and can be translucent or opaque.

Thermoset Resin

Thermoset resin is another type of resin used in 3D printing. Unlike photopolymer resin, thermoset resin undergoes a chemical reaction that creates a strong bond when heated. Once thermoset resin has cured, it becomes rigid and cannot be melted or reshaped. This makes it highly durable and suitable for applications that require strength or heat resistance.

Thermoplastic Resin

Thermoplastic resin is a type of resin that becomes malleable when heated and solidifies when cooled. This allows for greater flexibility and post-processing options compared to thermoset resin. Thermoplastic resin is often used in industrial applications as it offers excellent mechanical properties and is resistant to high temperatures and chemicals.

Advantages of Resin 3D Printing

High Level of Detail

Resin 3D printing offers an unparalleled level of detail and precision. The liquid resin is capable of capturing intricate details and fine features that may be difficult to achieve with other 3D printing technologies. This makes resin 3D printing an excellent choice for applications such as jewelry making, dental models, and architectural models.

Smooth Surface Finish

One of the key advantages of resin 3D printing is the smooth surface finish it provides. The liquid resin allows for the creation of objects with a smooth and polished appearance. This eliminates the need for extensive post-processing and sanding, saving time and effort in finishing the printed objects.

Wide Range of Colors

Resin 3D printing offers a wide range of color options, allowing users to create objects in vibrant and customized colors. The photopolymer resin used in this process can be mixed with various pigments, enabling the production of objects with different shades and hues. This is especially beneficial for applications such as product design, art, and jewelry.

Durability and Strength

Resin 3D printed objects can exhibit excellent mechanical properties, making them durable and strong. Depending on the type of resin used, the printed objects can possess high impact resistance, heat resistance, and chemical resistance. This makes resin 3D printing suitable for functional parts and prototypes that require structural integrity.

Disadvantages of Resin 3D Printing

Limited Size and Volume

One of the limitations of resin 3D printing is the limited build size and volume. The resin tanks used in SLA printers have a finite capacity, restricting the maximum size of objects that can be printed. Additionally, printing larger objects can also lead to longer print times, as the process requires layer-by-layer curing of the resin.

Higher Cost

Resin 3D printing can be more expensive compared to other 3D printing technologies. The cost of resin materials is generally higher than filament used in FDM printers. Additionally, resin 3D printers themselves tend to be pricier due to the precision components and light sources required for the printing process. However, as the technology advances and becomes more widely adopted, the cost is expected to decrease.

Toxicity and Safety Concerns

Resin 3D printing involves working with liquid resin, which can emit volatile organic compounds (VOCs) during the printing process. These VOCs can be harmful to health, causing eye, nose, and throat irritation. It is essential to operate resin printers in a well-ventilated area or use dedicated air filtration systems to minimize exposure to VOCs. Proper safety precautions, such as wearing protective gloves and goggles, should also be taken when handling the uncured resin.

This image is property of images.unsplash.com.

Key Components of a Resin 3D Printer

Resin Tank

The resin tank is a crucial component of a resin 3D printer. It holds the liquid resin and provides a stable platform for the printing process. The resin tank needs to be made of a material that is resistant to the chemical reactions that occur during printing and can withstand the exposure to light sources.

Build Platform

The build platform is where the printed object is built layer by layer. It moves up incrementally as each layer is cured, allowing for the construction of complex 3D shapes. The build platform needs to be precisely calibrated to ensure accurate printing and proper adhesion of each layer.

Light Source

The light source is responsible for curing the liquid resin. It can be a laser or a UV light, depending on the printer’s technology. The light needs to have the right intensity and wavelength to solidify the resin effectively and ensure proper curing of each layer.

Control System

The control system of a resin 3D printer manages the entire printing process. It controls the movement of the build platform, the curing of the resin, and the timing of each layer. The control system must be precise to achieve accurate and consistent printing results.

How Does Resin 3D Printing Work?

Preparation of 3D Model

The first step in resin 3D printing is preparing a 3D model of the object to be printed. This can be done using 3D modeling software or by downloading a pre-designed model from an online repository. The 3D model needs to be exported in a format compatible with the printer software.

Slicing the Model

Once the 3D model is ready, it needs to be sliced into thin layers. Slicing software is used to divide the model into numerous cross-sectional layers that the printer can understand. Each layer is then converted into a set of instructions that the printer can follow.

Printing Process

The resin 3D printing process begins by filling the resin tank with the liquid resin. The build platform is positioned near the top of the resin tank, just above the liquid resin. The printer’s light source then emits a specific wavelength of light, selectively curing the resin according to the sliced model’s instructions. The build platform gradually moves down with each layer, allowing for the build-up of the final object.

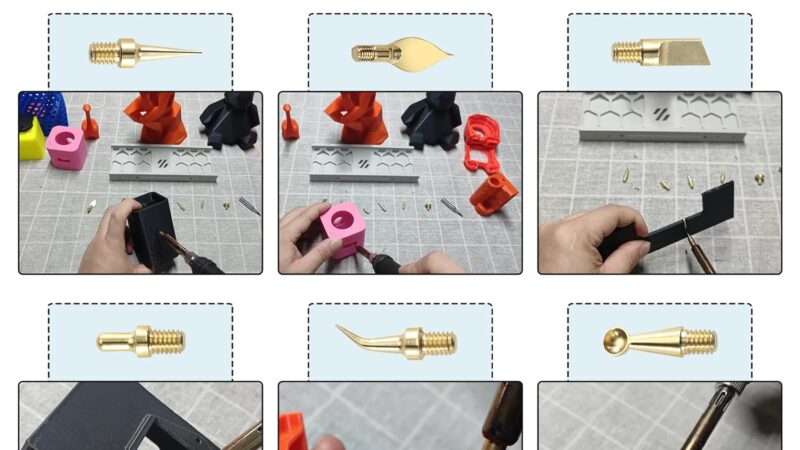

Post-processing

Once the printing process is complete, the printed object is removed from the printer. It is usually covered in uncured resin and requires post-processing. Post-processing may involve rinsing the object in a solvent to remove excess resin, curing it further under UV light to ensure complete hardening, and performing any necessary sanding or polishing to achieve the desired finish.

This image is property of images.unsplash.com.

Applications of Resin 3D Printing

Prototyping and Product Development

Resin 3D printing is widely used in prototyping and product development. Its ability to produce highly detailed and accurate models makes it an invaluable tool for designers, engineers, and manufacturers. With resin 3D printing, it is possible to create prototypes that closely resemble the final product, allowing for testing, evaluation, and design optimization.

Dental and Medical Applications

Resin 3D printing has revolutionized the dental and medical industries. It enables the production of highly precise dental models, orthodontic aligners, surgical guides, and prosthetics. Resin 3D printing allows for the customization and mass production of dental and medical devices that fit each patient’s unique requirements, leading to improved patient outcomes and reduced treatment time.

Art and Jewelry

Resin 3D printing offers endless possibilities for artists and jewelers to create intricate and personalized pieces. Artists can design and print sculptures, statues, and art installations with a level of detail that was previously unachievable. Jewelers can use resin 3D printing to produce custom-designed pieces, including rings, pendants, and bracelets, allowing for more creativity and personalization.

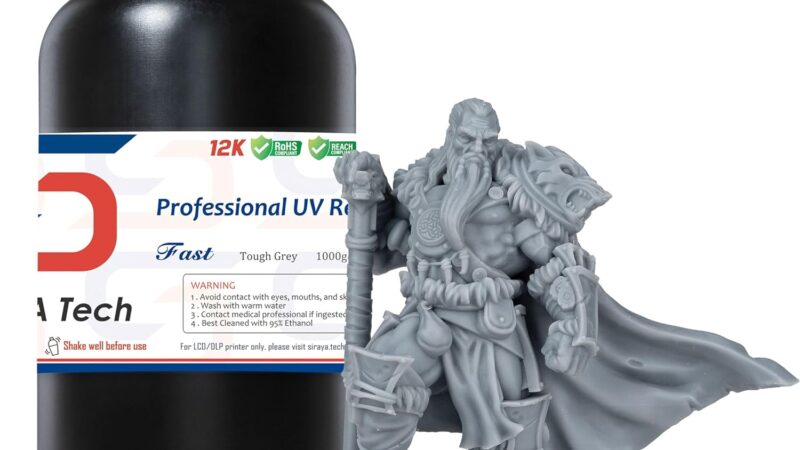

Miniatures and Tabletop Gaming

Resin 3D printing has become increasingly popular in the hobbyist community, particularly in the realm of tabletop gaming. Gaming enthusiasts can now create their custom miniatures, terrain, and props, breathing life into their gaming worlds. The high level of detail and precision offered by resin 3D printing enhances the gaming experience, allowing for more immersive and visually stunning gameplay.

Tips for Successful Resin 3D Printing

Choosing the Right Resin

Selecting the appropriate resin for your specific requirements is crucial. Consider factors such as mechanical properties, heat resistance, and color options when choosing a resin. It is also important to ensure compatibility with your 3D printer, as different printers may require specific resins.

Calibrating the Printer

Proper calibration of the resin 3D printer is essential for achieving accurate and consistent results. Calibration involves adjusting the build platform, ensuring levelness and proper adhesion of each layer. Additionally, the curing time and light intensity should be optimized based on the specific resin being used.

Proper Handling and Storage of Resin

Resin should be handled with care to minimize exposure to skin and eyes. Always wear gloves and goggles when handling uncured resin. Resin should also be stored in a cool, dry place away from direct sunlight to avoid premature curing or degradation.

Implementing Supports

When printing objects with overhangs or complex geometries, supports may be required. These supports help ensure proper layer adhesion and prevent sagging or deformation during printing. It is important to properly design and place supports to minimize post-processing and achieve the desired end result.

Comparison with Other 3D Printing Technologies

Resin vs. FDM 3D Printing

Resin 3D printing has several advantages over FDM (Fused Deposition Modeling) 3D printing. Resin printing offers a higher level of detail, smoother surface finish, and greater color range compared to FDM printing. However, FDM printers tend to have larger build volumes and are more cost-effective for printing larger objects.

Resin vs. SLS 3D Printing

Resin 3D printing differs from SLS (Selective Laser Sintering) 3D printing in terms of materials and application. While SLS printing uses powdered materials, such as nylon or metal, resin printing uses liquid photopolymer resin. Resin printing generally offers higher precision and finer details, but SLS printing excels in producing functional prototypes and end-use parts with mechanical strength.

Resin vs. Inkjet 3D Printing

Inkjet 3D printing and resin 3D printing share some similarities, as both use liquid materials for printing. However, inkjet 3D printing is typically used for full-color printing with less emphasis on high resolution and surface finish. Resin printing provides superior detail and finish but may require more post-processing compared to inkjet printing.

Future Developments in Resin 3D Printing

Improved Resin Formulations

As resin 3D printing continues to evolve, there will likely be advancements in resin formulations. New resin materials may be developed, offering enhanced mechanical properties, improved heat resistance, and greater flexibility. These advancements will expand the range of applications for resin 3D printing.

Faster Printing Speeds

Efforts are being made to increase the printing speed for resin 3D printers. This will significantly reduce the print time for objects, making the technology more efficient and practical for various industries. Faster printing speeds will also contribute to improved productivity in prototyping and manufacturing processes.

Larger Build Volumes

The limitations of build size and volume in resin 3D printing are being addressed, with ongoing research and development to increase the capacity of the printers. With larger build volumes, users will have the ability to create bigger objects, opening the door to new applications in various industries.

Resin 3D printing continues to evolve and find applications in a wide range of industries. As technology advances, improvements in resin formulations, printing speeds, and build volumes will further enhance the capabilities of resin 3D printers. With its high level of detail, smooth surface finish, and versatility, resin 3D printing is set to play a pivotal role in the future of additive manufacturing.