The Fastest 3D Printer Ever

Imagine a world where you can transform your wildest ideas into physical objects in the blink of an eye. A world where creativity knows no bounds and innovation is limited only by your imagination. Well, my friend, allow me to introduce you to “The Fastest 3D Printer Ever.”

In this groundbreaking article, we will delve into the extraordinary capabilities of this technological marvel. Brace yourself, because you’re about to witness a game-changer that will revolutionize the way we create and manufacture. From its lightning-fast printing speed to its unparalleled precision, this 3D printer is poised to leave you in awe. So, sit back, relax, and prepare to be amazed as we explore the incredible possibilities that lie ahead.

Overview of 3D Printing

Definition of 3D Printing

3D printing, also known as additive manufacturing, is a revolutionary technology that allows the creation of three-dimensional objects by layering materials, such as plastic or metal, based on a digital model. Unlike traditional manufacturing methods that involve subtractive processes, 3D printing builds objects from the ground up, layer by layer. This innovative technique has garnered immense interest and has the potential to reshape various industries.

Importance of 3D Printing in Various Industries

The emergence of 3D printing has had a profound impact on numerous industries, including manufacturing, healthcare, art and design, and engineering. This technology enables companies to streamline production processes, reduce costs, and create complex and customized objects with exceptional precision. From prototyping and product development to tool and mold making, 3D printing has revolutionized the way industries approach manufacturing and design.

Evolution of 3D Printing Technology

Over the years, 3D printing technology has evolved significantly. From the early days of limited capabilities and high costs, 3D printers have become more accessible, affordable, and efficient. The increasing demand for faster and more reliable 3D printers has led to the development of cutting-edge technologies that push the boundaries of what was previously considered possible. One such breakthrough is fast 3D printing, which offers remarkable advantages in terms of speed, precision, and material compatibility.

Introduction to Fast 3D Printing

What is Fast 3D Printing?

Fast 3D printing refers to a category of 3D printers that are designed to optimize the printing process for speed without compromising on quality. These printers utilize advanced technologies and innovative techniques to significantly reduce the time required to produce three-dimensional objects. With fast 3D printing, what used to take hours or even days can now be accomplished in a fraction of the time.

Advantages of Fast 3D Printing

The main advantage of fast 3D printing is, of course, its speed. This enables manufacturers and designers to accelerate their production cycles, meet tight deadlines, and keep up with ever-evolving consumer demands. Additionally, fast 3D printing reduces lead times, allowing for more efficient prototyping and faster product iterations. The shorter printing time also contributes to increased productivity and cost savings.

Applications of Fast 3D Printing

The applications of fast 3D printing are diverse and far-reaching. Rapid prototyping is a common use case, allowing designers to quickly iterate on their concepts and bring products to market faster. Industries such as aerospace and automotive benefit from the ability to 3D print complex and lightweight components within shorter timeframes. Fast 3D printing is also gaining traction in the medical and dental fields, where it enables the production of patient-specific implants and prosthetics with enhanced efficiency.

Features of the Fastest 3D Printer Ever

Speed

The fastest 3D printer ever developed boasts incredible print speeds, significantly outperforming conventional 3D printers. With cutting-edge mechanisms and optimized processes, this printer is capable of completing complex prints in record time. The revolutionary technology behind it ensures that no time is wasted during the printing process, maximizing productivity and efficiency.

Precision

Despite its exceptional speed, the fastest 3D printer ever does not compromise on precision. It delivers outstanding print quality with unparalleled accuracy and intricacy. The advanced motion control systems and software algorithms work in perfect synchronization to ensure that every layer is precisely placed, resulting in flawless and high-resolution prints.

Layer Thickness

The fastest 3D printer ever offers the flexibility to adjust the layer thickness, allowing users to customize the level of detail and speed according to their specific requirements. This feature is particularly valuable when it comes to large-scale prints, enabling faster printing of thicker layers while still maintaining impressive quality.

Build Volume

With an expansive build volume, the fastest 3D printer ever provides ample space to accommodate large objects or multiple smaller prints simultaneously. This maximizes productivity and efficiency by reducing the need for multiple printing runs or assembly processes.

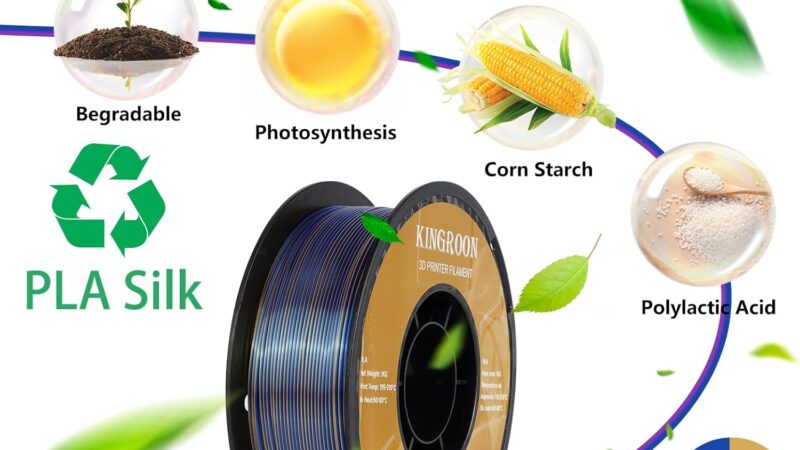

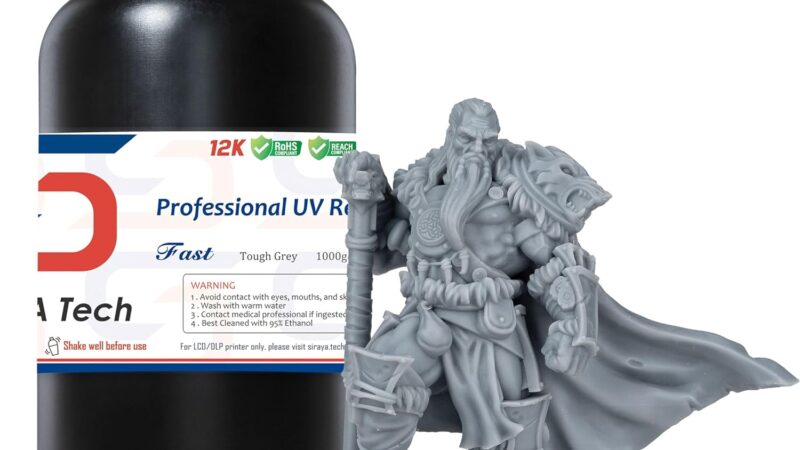

Compatibility with Various Materials

The fastest 3D printer ever is designed to be compatible with a wide range of materials, including plastics, metals, and even ceramics. This versatility allows users to explore various applications and experiment with different materials to meet their unique needs. Whether it’s rapid prototyping with ABS plastic or aerospace components made of titanium, this printer can handle it all.

Technology Behind the Fastest 3D Printer

Advanced Motion Control Systems

The fastest 3D printer ever incorporates advanced motion control systems, utilizing high-speed motors and precision sensors to optimize movement and minimize any potential vibrations or inconsistencies. This ensures smooth and precise printing, even at extremely high speeds.

High-Speed Extrusion Techniques

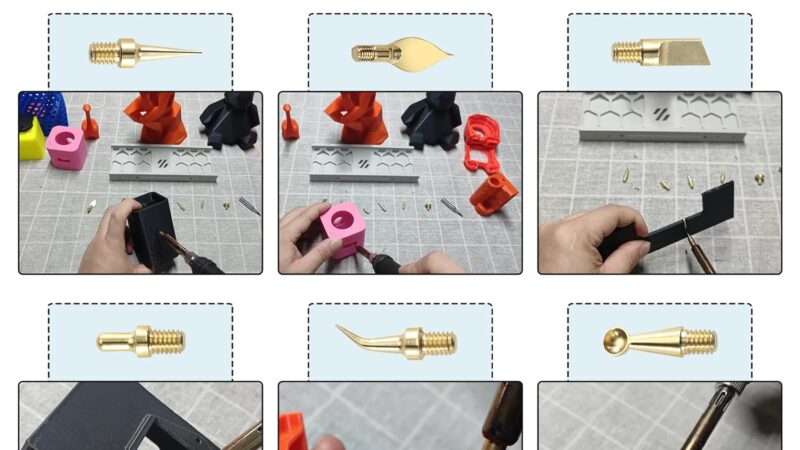

To achieve unprecedented speed, the fastest 3D printer utilizes high-speed extrusion techniques that allow for the rapid deposition of material. Cutting-edge extruders and nozzles enable faster material flow rates without compromising quality or detail.

Enhanced Cooling Mechanisms

The efficient cooling of freshly printed layers is crucial to maintain dimensional accuracy and prevent warping or deformities. The fastest 3D printer ever leverages enhanced cooling mechanisms, such as powerful fans and optimized airflow, to quickly cool each layer, allowing for faster printing cycles.

Optimized Software Algorithms

The software algorithms driving the fastest 3D printer ever play a crucial role in its incredible speed and precision. These algorithms are continuously optimized to minimize printing time, optimize layer placement, and ensure optimal material flow, resulting in efficient and flawless prints.

Comparison with Conventional 3D Printing Methods

Speed Comparison

When compared to conventional 3D printing methods, the fastest 3D printer ever showcases a tremendous advantage in terms of speed. While conventional printers may require hours or even days to complete a print, the fast printer can accomplish the same task in a fraction of the time, significantly reducing lead times and improving overall productivity.

Quality Comparison

While speed is a remarkable feature, it is equally important to consider the quality of the prints. The fastest 3D printer ever excels in maintaining exceptional quality and precision, ensuring that even at high speeds, the prints exhibit outstanding detail and accuracy. In contrast, conventional printers may struggle to maintain the same level of quality when pushed to their limits.

Material Compatibility Comparison

Conventional 3D printers often have limitations in terms of the materials they can process. The fastest 3D printer ever, on the other hand, is designed to be compatible with a wide range of materials, from standard plastics to advanced metals. This versatility opens up endless possibilities for different industries and applications.

Affordability and Cost Comparison

With advancements in technology, the cost of fast 3D printing has become increasingly affordable. While the initial investment in the fastest 3D printer ever may be higher compared to conventional printers, the increased efficiency, reduction in lead times, and improved overall productivity make it a cost-effective choice in the long run, especially for industries with high-volume production requirements.

Industrial Applications of the Fastest 3D Printer

Prototyping and Product Development

Fast 3D printing has revolutionized the prototyping and product development process. Designers and engineers can quickly produce functional prototypes and iterate on their designs in a matter of hours, greatly accelerating the time-to-market for new products.

Customized Manufacturing

The fastest 3D printer ever enables customized manufacturing on a large scale. From creating personalized consumer goods to producing customized medical devices, this technology allows for the efficient production of highly tailored products without the need for costly and time-consuming manual labor.

Tool and Mold Making

In manufacturing, tool and mold making is an essential process. The speed and precision of the fastest 3D printer ever make it an ideal tool for creating molds and tooling components, eliminating the need for traditional machining methods and reducing production time significantly.

Aerospace and Automotive Applications

The aerospace and automotive industries demand lightweight and complex components. The fastest 3D printer ever can produce intricate parts with exceptional speed and precision, making it an invaluable tool for these industries’ manufacturing processes.

Medical and Dental Applications

The medical and dental fields have embraced fast 3D printing due to its ability to produce patient-specific implants, prosthetics, and dental models. The speed of the printer allows healthcare professionals to provide faster and more personalized treatments, improving patient care and outcomes.

Impact on Various Industries

Manufacturing Industry

The fastest 3D printer ever has transformed the manufacturing industry by offering increased productivity, reduced lead times, and enhanced customization possibilities. It allows manufacturers to stay competitive in an ever-changing market and adapt to consumer demands quickly.

Healthcare Industry

In the healthcare industry, the fastest 3D printer ever has revolutionized various aspects, such as prosthetics, surgical planning, and bioprinting. It has opened doors to personalized treatments, improved surgical outcomes, and advancements in regenerative medicine.

Art and Design Industry

Fast 3D printing has unleashed a new wave of creativity in the art and design industry. Artists and designers can bring their intricate concepts to life rapidly and experiment with new techniques and materials, pushing the boundaries of traditional art forms.

Engineering and Construction Industry

The fastest 3D printer ever has the potential to transform the engineering and construction industry by enabling the rapid production of complex building components, such as architectural models, prefabricated elements, and even entire structures. This technology offers unprecedented design freedom, reduced construction time, and enhanced sustainability.

Challenges and Future Developments

Technical Limitations

While the fastest 3D printer ever provides impressive speed and quality, there are still technical limitations to overcome. Issues like material compatibility, print reliability, and scalability are areas that require ongoing research and development.

Materials Research and Development

Expanding the range of materials compatible with fast 3D printing is a key area of focus for future developments. Researchers and manufacturers are continuously exploring new materials, such as advanced composites and bio-compatible polymers, to unlock even more possibilities for this technology.

Integration with Industry 4.0

The integration of the fastest 3D printer ever with Industry 4.0 principles, such as automation, connectivity, and data-driven decision-making, holds immense potential. Fully embracing the digital transformation and harnessing the power of data can further optimize the printing process, enable remote monitoring and control, and improve overall efficiency.

Advancements in Automation and Robotics

Fast 3D printing can benefit from advancements in automation and robotics. The incorporation of robotic arms and intelligent systems can enhance the speed, precision, and scalability of the printing process, opening up new possibilities for large-scale production and complex designs.

Best Brands and Models of Fast 3D Printers

Brand A

Brand A offers one of the fastest 3D printers on the market, with remarkable speed and exceptional print quality. Their models are known for their reliability, versatility, and compatibility with an extensive range of materials.

Brand B

Brand B specializes in high-speed 3D printers that excel in large-scale production and industrial applications. Their models offer impressive build volumes, precise motion control systems, and seamless integration with automated workflows.

Brand C

Brand C is renowned for its cutting-edge fast 3D printers that combine speed, precision, and affordability. Their models have gained popularity among small to medium-sized businesses looking to enhance productivity and reduce production costs.

Brand D

Brand D stands out for its user-friendly interface, advanced software algorithms, and exceptional customer support. Their fast 3D printers are known for their seamless integration with industry-specific software and offer a wide range of customization options.

Conclusion

Fast 3D printing has revolutionized the way industries approach manufacturing and design. With the fastest 3D printer ever, manufacturers and designers can achieve exceptional speed, precision, and flexibility without compromising on quality. This technology has found valuable applications in various industries, from rapid prototyping to customized manufacturing and complex component production. As research and development continue to push the boundaries of fast 3D printing, the future prospects and market potential for this technology are indeed promising. With ongoing advancements in automation, material compatibility, and integration with Industry 4.0, fast 3D printing is poised to make an even greater impact on industries worldwide.